Product Description:

Power System Protection

Power system protection is a critical aspect of electrical engineering, aimed at ensuring the safe and reliable operation of electrical power networks. It involves the use of various devices and techniques to detect faults and abnormal conditions within the power system, thereby preventing damage to equipment and maintaining stability in the power supply.

The primary goal of power system protection is to isolate the faulty section of the network as quickly as possible, minimizing the impact on the rest of the system. Protective relays, circuit breakers, and transformers work in tandem to identify and respond to issues such as short circuits, overloads, and equipment failures.

Modern power system protection also incorporates advanced technologies like digital relays and communication networks, allowing for more precise fault detection and faster response times. This enhances the resilience of the power grid and supports the integration of renewable energy sources.

Overall, effective power system protection is essential for ensuring continuous power delivery, safeguarding infrastructure, and enhancing the overall efficiency of electrical power systems.

Features:

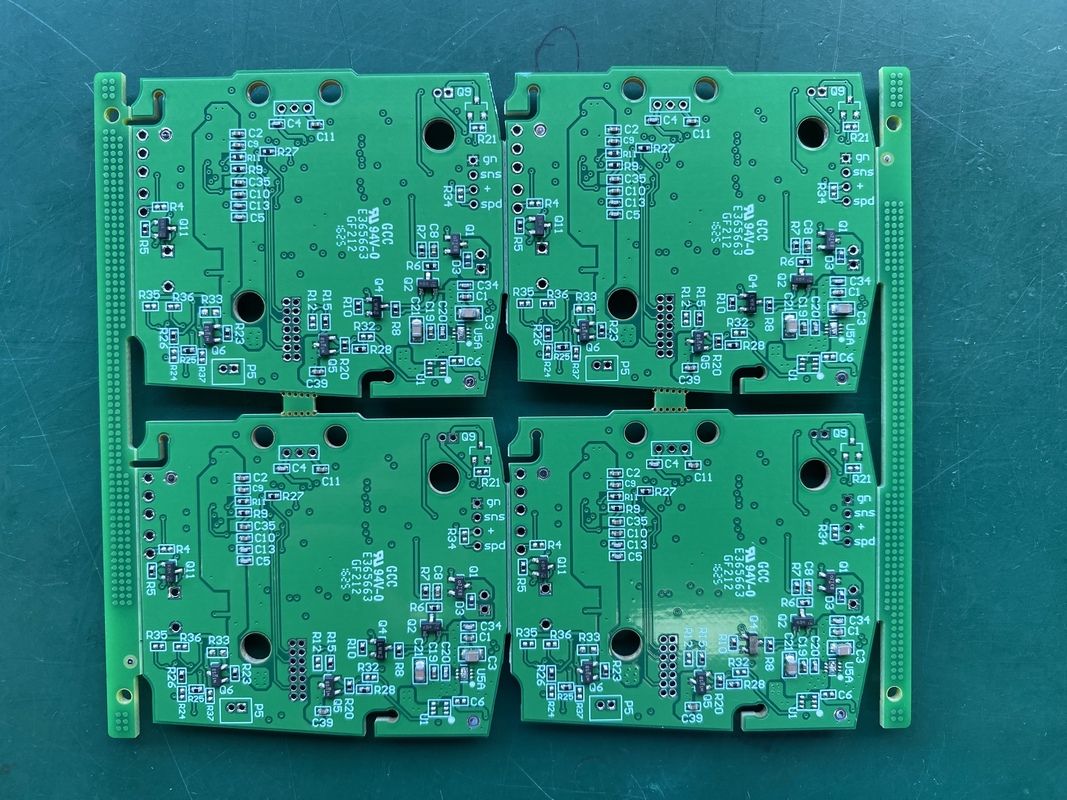

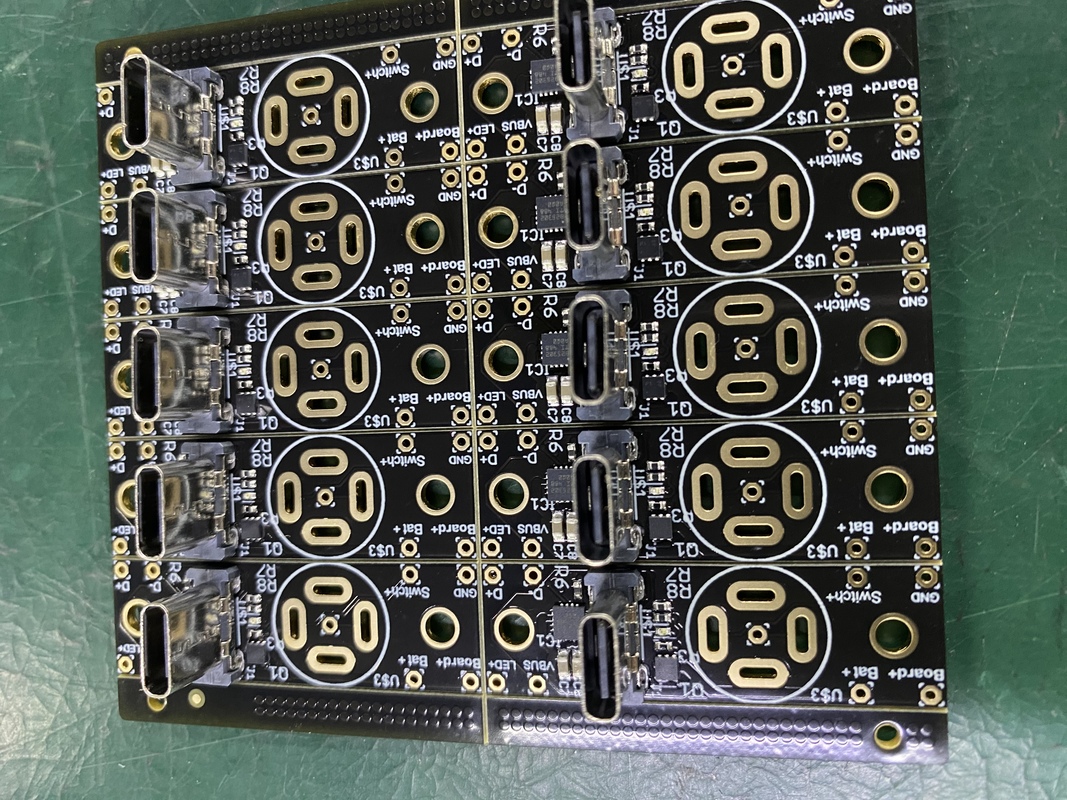

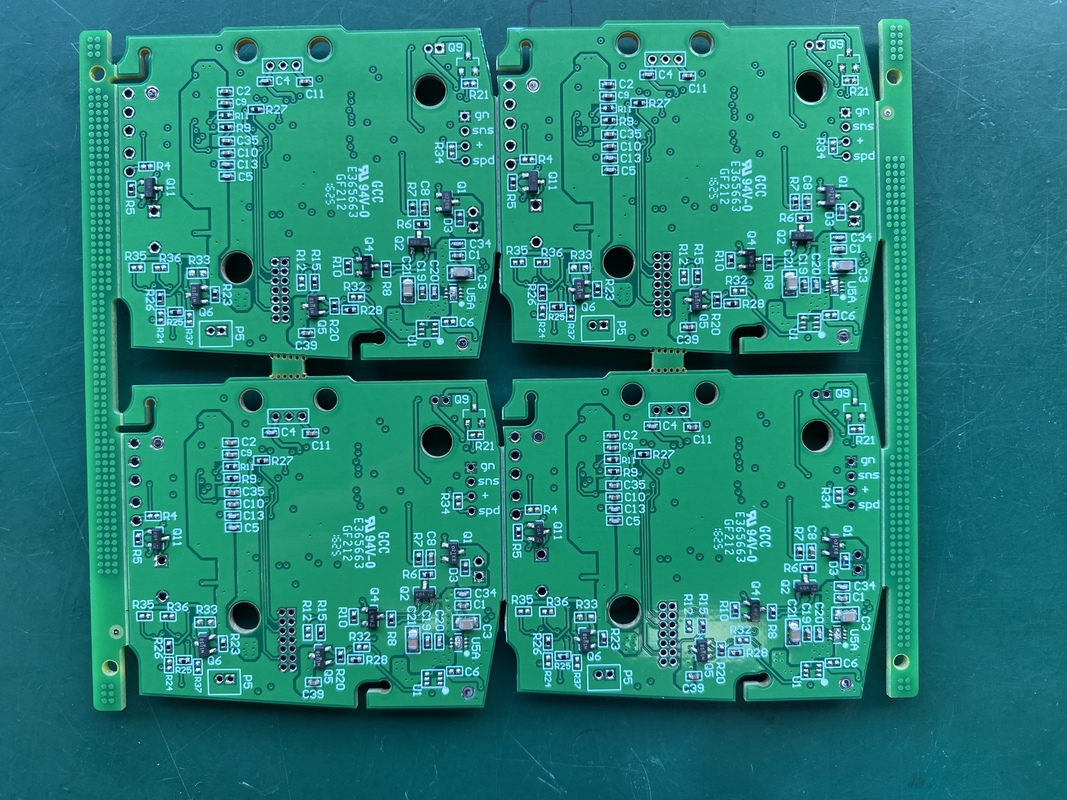

- Product Name: Power Protection PCB Assembly

- Min. Line Width/Spacing: 0.1mm

- Silkscreen Color: White

- Thickness: 1.6mm

- Max. Operating Temperature: 125°C

- Certificates: ISO9001, ISO13485, IATF16949, and UL

- Energy Safeguarding PCB Assembly designed for reliable performance

- Voltage Protection PCB Assembly ensuring stable voltage regulation

- Power Protection Printed Circuit Board Assembly optimized for durability and safety

Technical Parameters:

| Soldermask | Blue, Green, Black, Red, Matt Color |

| Customized | Yes |

| Size At Max | 1200*400mm |

| Certifications | UL, RoHS |

| Silkscreen Color | White |

| Thickness | 1.6mm |

| Product Compliance | ROHS |

| Guarantee | 1 Year |

| Min. Line Width/Spacing | 0.1mm |

| Max. Operating Temperature | 125°C |

Applications:

The industrial sector plays a crucial role in the economy, driving innovation and production across various fields. Advances in technology and manufacturing processes have significantly boosted industrial output and efficiency.

The electric vehicle (EV) industry is rapidly transforming the automotive landscape. With growing environmental concerns and advancements in battery technology, EV cars are becoming more accessible and popular among consumers worldwide.

Communication is an essential component of modern society, enabling seamless interaction and information exchange. From traditional methods to cutting-edge digital platforms, communication continues to evolve and connect people globally.

Capital construction involves the development of large-scale infrastructure projects. These initiatives are vital for supporting economic growth, improving public services, and enhancing the overall quality of life.

Customization:

Our Power Protection Printed Circuit Board Assembly services are designed to meet the highest industry standards, ensuring reliable and efficient power shielding solutions. Manufactured in China or Cambodia, each Power Shielding PCB Assembly undergoes rigorous quality control with certifications including ISO9001:2015, ISO13485:2016, IATF 16949:2016, and UL E476377, guaranteeing superior performance and safety.

We offer flexible customization options with a minimum order quantity of just 1 piece, making it convenient for both small-scale prototypes and large production runs of Power Security PCB Assembly. Pricing is available upon request to provide tailored solutions that best fit your project requirements.

Our packaging solutions include ESD bags and shield bags to protect your assemblies during transit, while delivery times are to be confirmed based on order specifics. Payment terms are straightforward with TT accepted for smooth transactions.

Choose from a variety of soldermask colors including Blue, Green, Black, Red, White, and Matt Color to match your design preferences. Our Power Protection PCB Assembly supports precise hole sizes down to 0.1mm, ensuring compatibility with intricate circuit designs. Additionally, all products comply with UL and RoHS certifications to meet environmental and safety standards.

Support and Services:

Our Power Protection PCB Assembly is designed to provide reliable and efficient power management and protection for a variety of electronic devices. To ensure optimal performance and longevity of the product, we offer comprehensive technical support and services.

Our technical support team is available to assist with installation guidance, troubleshooting, and maintenance procedures. We provide detailed documentation, including user manuals, wiring diagrams, and specification sheets to help users understand and utilize the product effectively.

In the event of a malfunction or failure, we offer diagnostic services to identify issues and recommend appropriate corrective actions. Replacement parts and repair services are available to minimize downtime and ensure your system remains protected.

We also provide firmware updates and software tools as applicable to maintain compatibility with evolving system requirements and to enhance functionality.

For custom applications, our engineering team can offer consultation services to tailor the Power Protection PCB Assembly to meet specific operational needs, ensuring seamless integration into your system.

Regular maintenance and inspection services are recommended to maintain the performance and safety standards of the product over its operational life.

Our commitment is to support our customers with timely and effective service to maximize the value and reliability of the Power Protection PCB Assembly.

Packing and Shipping:

Each Power Protection PCB Assembly is carefully packaged to ensure maximum protection during transit. The assembly is first placed in an anti-static bag to prevent electrostatic discharge damage. It is then secured within a custom-fitted foam insert to cushion against shocks and vibrations. The foam insert is enclosed in a sturdy cardboard box designed to withstand handling and stacking.

For shipping, we use reliable courier services with tracking and insurance options to guarantee safe delivery. The packages are clearly labeled with handling instructions such as “Fragile” and “Handle with Care” to minimize the risk of damage. We also provide detailed documentation, including packing lists and user manuals, inside the package for your convenience.

In addition, bulk orders are palletized and shrink-wrapped to ensure stability and protection throughout the shipping process. Our packaging and shipping protocols comply with industry standards to maintain the quality and functionality of the Power Protection PCB Assembly from our facility to your destination.

FAQ:

Q1: Where is the Power Protection PCB Assembly manufactured?

A1: The Power Protection PCB Assembly is manufactured in China or Cambodia.

Q2: What certifications does this product have?

A2: It is certified with ISO9001:2015, ISO13485:2016, IATF 16949:2016, and UL E476377.

Q3: What is the minimum order quantity for the Power Protection PCB Assembly?

A3: The minimum order quantity is 1 piece.

Q4: How is the product packaged?

A4: The product is packaged in ESD bags and shield bags to ensure protection during shipping.

Q5: What are the payment terms and delivery time?

A5: Payment is accepted via TT (Telegraphic Transfer). The delivery time is to be confirmed upon order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!