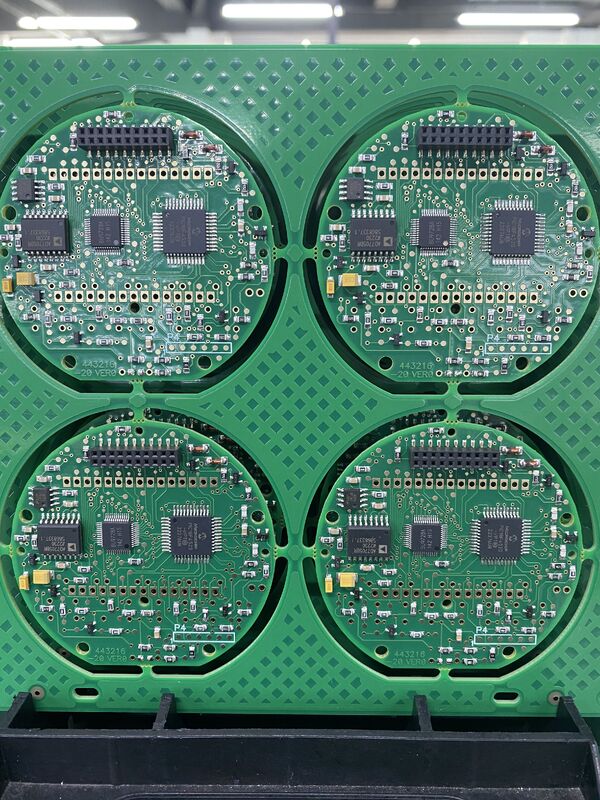

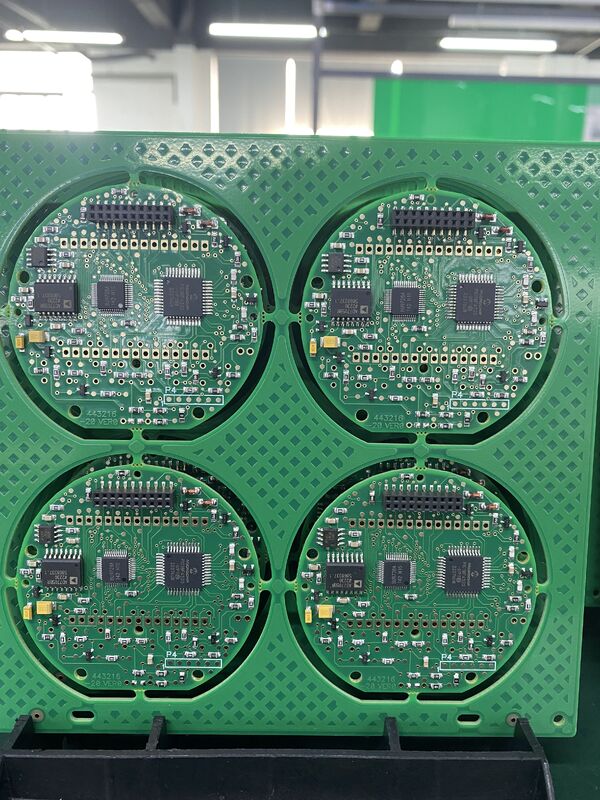

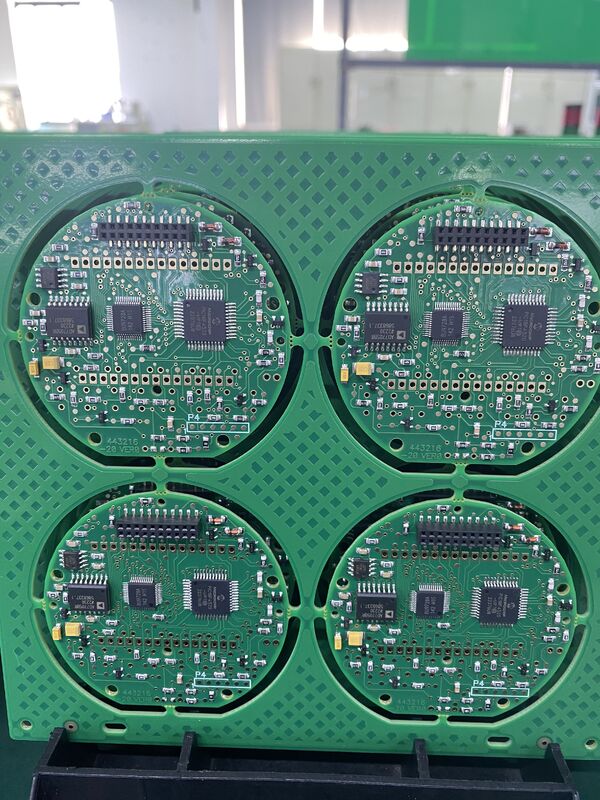

Product Description:

Industrial PCB Assembly plays a crucial role in the manufacturing and functionality of various electronic devices used across multiple industries. Our Industrial Printed Circuit Board Assembly service is designed to meet the demanding requirements of modern industrial applications, ensuring high performance, reliability, and durability. With a focus on quality and precision, our Industrial Electronic Board Assembly solutions cater to a wide range of industrial needs, making us a trusted partner for businesses seeking advanced electronic circuit solutions.

One of the standout features of our Industrial PCB Assembly is the versatility in thickness, ranging from 0.3mm to 6mm. This broad spectrum allows us to accommodate different design specifications and mechanical requirements, ensuring that the assembled boards can withstand various operational stresses and environmental conditions. Whether your project requires ultra-thin PCBs for compact devices or thicker boards for enhanced durability and heat dissipation, we have the capability to deliver precisely tailored solutions.

We understand that size matters in industrial applications, which is why our maximum PCB size extends up to 600*1200mm. This large format capability enables us to handle complex and sizable industrial electronic circuit assemblies, supporting sophisticated designs and multi-layered configurations. Our capacity to work with large PCBs ensures that your industrial electronic board assembly projects are not limited by size constraints, allowing for innovative and expansive circuit designs.

Material selection is pivotal to the performance and longevity of Industrial Printed Circuit Board Assemblies. Our assemblies utilize high-quality materials such as FR4, CEM-1, and CEM-3. FR4 is renowned for its excellent mechanical strength and electrical insulation properties, making it ideal for robust industrial applications. CEM-1 and CEM-3 provide cost-effective alternatives with reliable performance, suitable for various industrial electronic circuit assembly needs. By offering these material options, we empower our clients to choose the best fit for their specific industrial applications, balancing performance and budget considerations.

Impedance control is a critical aspect of Industrial Electronic Board Assembly, especially for high-frequency and high-speed signal applications. Our Industrial PCB Assembly services include precise impedance control, ensuring signal integrity and minimizing electromagnetic interference. This capability is essential for maintaining the functionality of complex electronic systems used in industrial automation, communication, and control equipment. With our expertise in impedance-controlled PCB manufacturing, we guarantee that your industrial electronic circuit assemblies meet stringent electrical performance standards.

Reliability is at the core of our Industrial Electronic Circuit Assembly services. We back our products with a comprehensive 1-year warranty, reflecting our confidence in the quality and durability of our assemblies. This warranty provides peace of mind to our clients, assuring them that any manufacturing defects or performance issues will be addressed promptly and professionally. Our commitment to quality assurance, combined with rigorous testing protocols, ensures that every Industrial Printed Circuit Board Assembly we deliver is ready to perform flawlessly in demanding industrial environments.

In summary, our Industrial PCB Assembly services offer a robust solution for businesses looking to develop high-quality, reliable, and precise industrial electronic boards. With a wide range of thickness options from 0.3mm to 6mm, support for large PCB sizes up to 600*1200mm, and the use of premium materials like FR4, CEM-1, and CEM-3, we provide tailored solutions that meet diverse industrial needs. Our expertise in impedance control further enhances the performance of your industrial electronic circuit assemblies, while our 1-year warranty underlines our commitment to excellence. Trust our Industrial Electronic Board Assembly services to deliver superior results that drive the success of your industrial applications.

Features:

- Product Name: Industrial PCB Assembly

- Max PCB Size: 600*1200mm

- Copper Thickness: 4OZ

- Usage: OEM Electronics

- Material Options: FR4, CEM-1, CEM-3

- Max Thickness: T > 4.5mm

- Specialized in Industrial Printed Circuit Board Assembly

- Expertise in Industrial PCB Manufacturing Assembly

- Advanced Industrial PCB Fabrication Assembly capabilities

Technical Parameters:

| Copper |

4OZ |

| Customized |

Yes |

| Solder Mask Color |

Green, Red, Blue, Black, White, Yellow |

| Material |

FR4, CEM-1, CEM-3 |

| Impedance Control |

Yes |

| PCB Thickness |

0.2-3.2mm |

| Max Thickness |

T>4.5mm |

| Base Material |

FR4 |

| Min Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| Usage |

OEM Electronics |

Applications:

Industrial Printed Circuit Assembly plays a crucial role in a wide range of application occasions and scenarios, particularly in sectors requiring high reliability and precision. With PCB thickness options ranging from 0.2mm to 3.2mm and copper thickness up to 4OZ, these assemblies are designed to meet the demanding needs of various industrial environments. The capability to handle maximum thicknesses greater than 4.5mm and overall thickness from 0.3mm to 6mm further enhances their versatility, making them suitable for complex and heavy-duty electronic devices.

One of the primary application occasions for Industrial PCB Fabrication Assembly is in OEM electronics manufacturing. These assemblies are essential for producing customized electronic components tailored to specific industrial machinery, control systems, and automation equipment. The robust design and precise fabrication ensure that the PCBs can withstand harsh operating conditions, including extreme temperatures, vibrations, and exposure to dust or moisture, which are common in industrial settings.

Industrial PCB Assembly Solutions are also widely used in sectors such as automotive, aerospace, telecommunications, and medical devices. In automotive applications, the PCBs must endure constant mechanical stress and temperature fluctuations, which is why the thickness and copper weight specifications are critical for durability and performance. Aerospace electronics demand high reliability and lightweight solutions, where the precise control over PCB thickness and copper layers ensures optimal functionality without adding unnecessary weight.

In telecommunications, Industrial Printed Circuit Assembly supports the construction of high-frequency and high-speed communication devices. The thickness range and heavy copper options facilitate efficient heat dissipation and electrical conductivity, which are vital for maintaining signal integrity and system stability. Similarly, in medical electronics, the reliable and customizable nature of Industrial PCB Fabrication Assembly allows for the creation of sophisticated diagnostic and monitoring equipment that requires consistent performance over long periods.

Overall, Industrial PCB Assembly Solutions provide a comprehensive and adaptable platform for various industrial applications that depend on durable, high-quality circuit boards. Whether it is for heavy machinery, precision instruments, or complex electronics, the combination of customizable thickness, heavy copper layers, and OEM compatibility ensures these assemblies meet the rigorous demands of modern industrial technology.

Customization:

Our Industrial PCB Assembly product offers comprehensive Industrial Electronics Assembly Service tailored to meet your specific requirements. We specialize in Industrial PCB Fabrication Assembly with high-quality materials, featuring 4OZ copper and thickness options ranging from 0.3mm to 6mm to ensure durability and optimal performance.

We provide a variety of silkscreen color options including white, black, yellow, and more to suit your design preferences. Our service includes 100% AOI, FCT, and ICT testing to guarantee the highest reliability and functionality of your PCBs.

Designed for OEM electronics, our Industrial PCB Fabrication Assembly ensures precise and efficient manufacturing, helping you achieve superior results in your electronic products.

Support and Services:

Our Industrial PCB Assembly product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide expert guidance throughout the entire lifecycle of the product, from initial design consultation to post-installation maintenance.

Our technical support team is equipped to assist with troubleshooting, software updates, and integration with existing systems. We offer detailed documentation, including user manuals, assembly instructions, and compliance certifications to facilitate seamless implementation.

Additionally, our services include customized training sessions for your engineering and maintenance staff, tailored to your specific operational requirements. We also provide repair and refurbishment options to extend the lifespan of your PCB assemblies.

With a commitment to quality and reliability, our support services aim to minimize downtime and maximize productivity, ensuring that your industrial applications run smoothly and efficiently.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each assembled PCB is enclosed in anti-static bags to prevent electrostatic discharge damage, followed by cushioning materials such as foam or bubble wrap to absorb shocks and vibrations.

The packaged PCBs are then placed in sturdy, corrugated cardboard boxes designed to withstand rough handling and stacking during shipping. For large orders, custom pallets and crates are available to provide additional security and stability.

We use reliable shipping services with tracking options to guarantee timely and safe delivery. All packages are clearly labeled with handling instructions and product information to facilitate smooth customs clearance and recipient handling.

Our packaging and shipping processes comply with industry standards to ensure that your Industrial PCB Assembly products arrive in perfect condition, ready for immediate use in your applications.

FAQ:

Q1: What types of components can be assembled on the Industrial PCB Assembly?

A1: Our Industrial PCB Assembly supports a wide range of components including SMD (Surface Mount Devices), through-hole components, BGAs (Ball Grid Arrays), and fine-pitch ICs to meet diverse industrial requirements.

Q2: What is the typical turnaround time for Industrial PCB Assembly orders?

A2: The standard turnaround time is usually between 7 to 14 business days, depending on the complexity and volume of the order. Expedited services are available upon request.

Q3: Do you provide testing and quality assurance for the assembled PCBs?

A3: Yes, each PCB assembly undergoes rigorous quality control processes including AOI (Automated Optical Inspection), X-ray inspection, and functional testing to ensure reliability and performance.

Q4: Can you handle large volume production runs for Industrial PCB Assembly?

A4: Absolutely. We have the capacity and expertise to manage both small prototype batches and large-scale production runs with consistent quality and timely delivery.

Q5: What file formats do you accept for PCB assembly design submissions?

A5: We accept industry-standard files such as Gerber, BOM (Bill of Materials), Pick and Place files, and IPC-2581 to facilitate accurate and efficient assembly of your PCBs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!