Product Description:

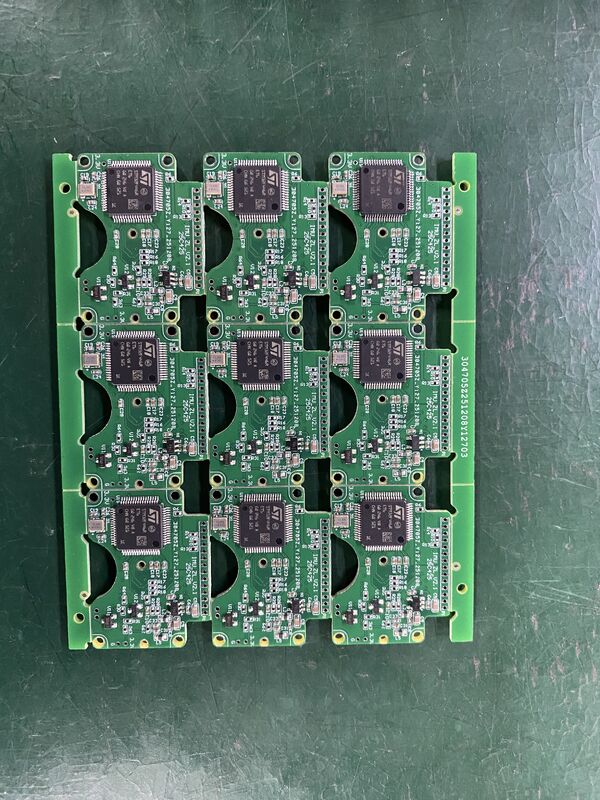

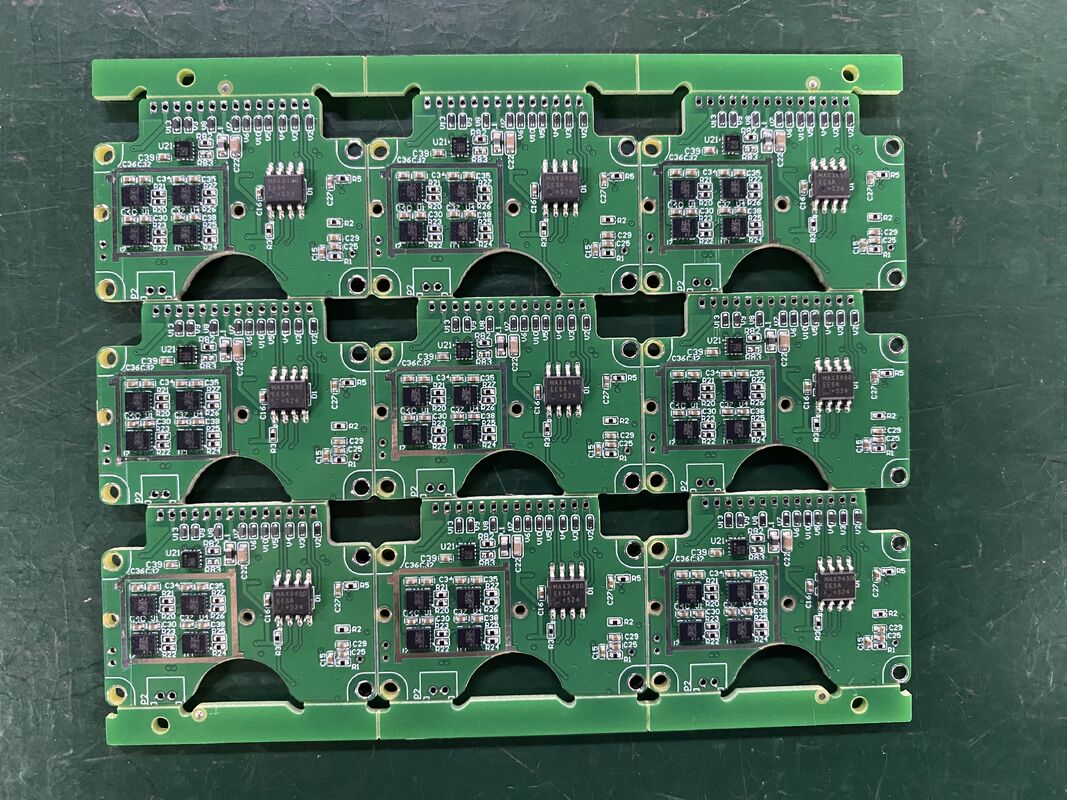

Our Industrial PCB Assembly product offers a comprehensive and reliable solution tailored specifically for demanding industrial applications. With a focus on quality, durability, and precision, this product is designed to meet the stringent requirements of modern industrial electronics. Utilizing a 4OZ copper layer, the PCB ensures excellent conductivity and enhanced thermal management, which is critical for industrial environments where high power and heat dissipation are common challenges. This robust copper thickness contributes to the overall reliability and longevity of the assembled PCBs, making them ideal for heavy-duty industrial use.

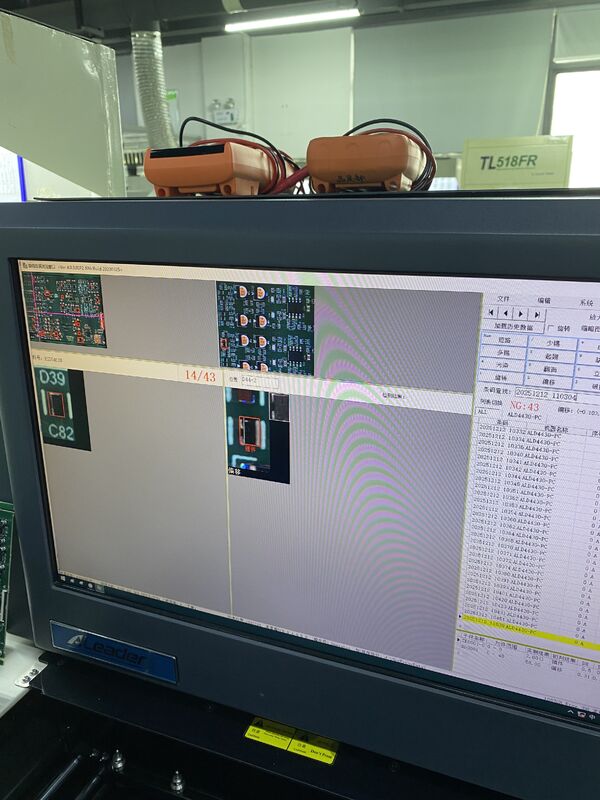

We pride ourselves on delivering top-notch Industrial PCB Assembly Solutions that incorporate advanced testing methodologies to guarantee flawless performance. Our testing service includes 100% Automated Optical Inspection (AOI), Functional Circuit Testing (FCT), and In-Circuit Testing (ICT). These comprehensive testing procedures are implemented at every stage of the assembly process to identify and rectify any potential defects, ensuring that each PCB assembly meets the highest standards of quality and functionality. This rigorous approach to testing minimizes the risk of failure in the field, thereby enhancing the reliability of your industrial electronic systems.

The base material used for our Industrial PCB Manufacturing Assembly is high-quality FR4, known for its excellent mechanical strength and electrical insulation properties. FR4 is a widely accepted standard in the industry, providing a stable and durable platform for complex circuit designs. Its superior flame retardance and moisture resistance make it exceptionally suitable for industrial environments where environmental conditions can be harsh and unpredictable. This choice of material ensures that the PCBs maintain their integrity and performance over extended periods, even under challenging operating conditions.

One of the critical features of our Industrial PCB Assembly Solutions is impedance control, which is essential for high-frequency and high-speed circuit applications commonly found in industrial electronics. Our precise impedance control capabilities allow for consistent signal integrity, reducing electromagnetic interference and signal loss. This ensures that your industrial PCB assemblies perform optimally in applications such as communication systems, control units, and sensor networks, where accurate signal transmission is paramount.

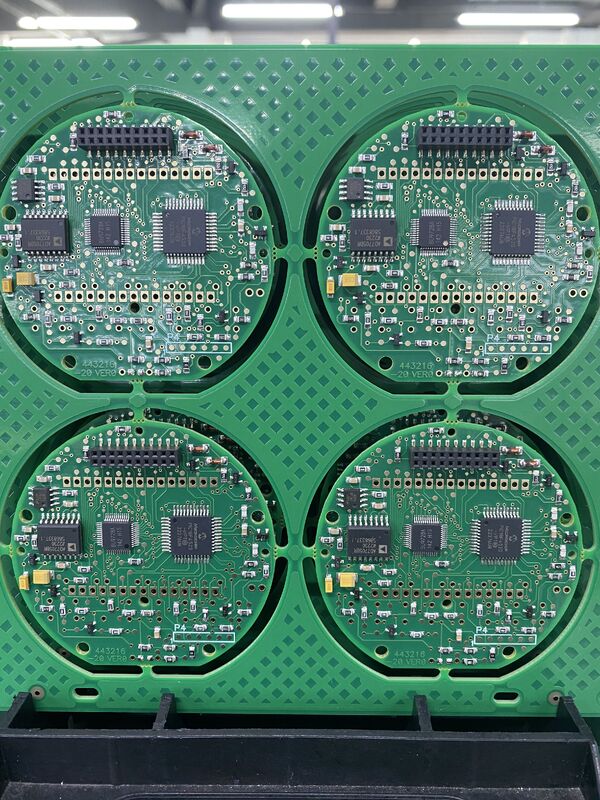

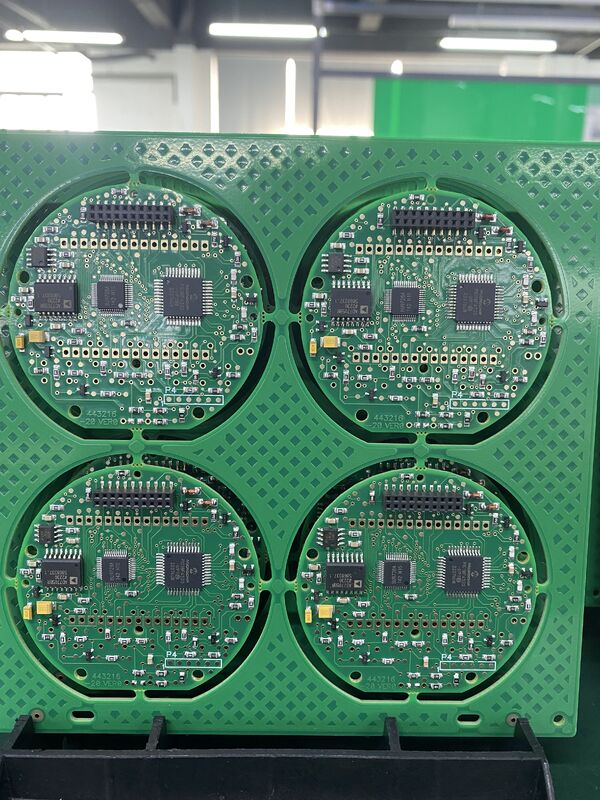

We accommodate a maximum PCB size of 600*1200mm, providing flexibility for large and complex industrial projects. This capability enables the production of sizable PCBs that can incorporate multiple components and intricate circuit designs without compromising structural integrity or performance. Whether you require single or multi-layer PCB assemblies, our manufacturing processes are optimized to handle large-format boards efficiently, catering to diverse industrial needs.

Our Industrial PCB Manufacturing Assembly services are designed to support a wide range of industrial sectors, including automotive, aerospace, telecommunications, and manufacturing automation. By choosing our Industrial PCB Assembly Solutions, you gain access to a partner committed to delivering high-quality, customized PCB assemblies that meet your specific operational requirements. We combine advanced technology, stringent quality control, and expert engineering to provide products that enhance the performance and reliability of your industrial electronic systems.

In summary, our Industrial PCB Assembly product is a robust and reliable solution featuring 4OZ copper for superior conductivity, 100% AOI, FCT, and ICT testing for guaranteed quality, impedance control for optimal signal integrity, and an FR4 base material for durability. Supporting large PCB sizes up to 600*1200mm, this product is engineered to meet the complex demands of industrial electronics. Trust our Industrial PCB Assembly Solutions to deliver exceptional performance, durability, and precision for your industrial manufacturing assembly needs.

Features:

- Product Name: Industrial Printed Circuit Board Assembly

- Maximum Thickness: T>4.5mm

- PCB Thickness Range: 0.2-3.2mm

- Minimum Ball Space: 0.3mm ≤ Pitch < 0.5mm

- Maximum PCB Size: 600*1200mm

- Impedance Control: Yes

- Designed specifically for Industrial Printed Circuit Board Assembly applications

- High precision suitable for Industrial Printed Circuit Board Assembly requirements

- Supports complex layouts typical in Industrial Printed Circuit Board Assembly

Technical Parameters:

| Base Material |

FR4 |

| Impedance Control |

Yes |

| Thickness |

0.3mm-6mm |

| Customized |

Yes |

| Usage |

OEM Electronics |

| Copper |

4OZ |

| PCB Thickness |

0.2-3.2mm |

| Testing Service |

100% AOI FCT ICT Testing |

| Max Thickness |

T>4.5mm |

| Min Ball Space |

0.3mm≤Pitch<0.5mm |

Applications:

The Industrial PCB Assembly product is meticulously designed to cater to a wide range of application occasions and scenarios across various industries. With its advanced Industrial PCB Manufacturing Process, this product ensures superior quality and reliability, making it ideal for use in complex industrial environments where precision and durability are paramount. The assembly process incorporates stringent impedance control, which is critical for maintaining signal integrity in high-frequency and high-speed industrial applications.

This Industrial Circuit Board Assembly is extensively used in manufacturing plants, automation systems, robotics, and control panels where customized solutions are often required. Thanks to its customizable nature, including options for silkscreen colors such as white, black, yellow, and others, it can be tailored to meet specific client requirements, enhancing both functionality and aesthetics. The ability to customize thickness from 0.3mm up to 6mm further broadens its suitability, allowing it to fit into a variety of industrial devices ranging from compact electronics to larger machinery components.

In harsh industrial settings, the durability and performance of PCB assemblies are crucial. This product offers a 1-year warranty, providing users with confidence in its long-term reliability and performance. The Industrial PCB Manufacturing Process employed guarantees that each board meets stringent quality standards, ensuring consistent performance even under demanding conditions such as extreme temperatures, vibrations, and electrical noise.

Typical application scenarios include industrial automation equipment, power supply units, instrumentation, communication devices, and embedded systems where robust and reliable circuit boards are essential. Additionally, this Industrial Circuit Board Assembly is suitable for custom industrial projects that require precise impedance control to minimize signal loss and electromagnetic interference.

Overall, the Industrial PCB Assembly product stands out as an excellent choice for industries seeking high-quality, customizable, and reliable circuit board solutions. Its combination of advanced manufacturing techniques, customizable options, and robust warranty makes it indispensable for modern industrial applications that demand both precision and durability.

Customization:

Our Industrial PCB Assembly product offers comprehensive Industrial PCB Assembly Solutions tailored to meet your specific requirements. We provide 100% AOI, FCT, and ICT testing services to ensure the highest quality and reliability of your Industrial Circuit Board Assembly. Choose from a variety of soldermask colors including Green, Red, Blue, Black, White, and Yellow to customize the appearance of your boards. We accommodate board thicknesses ranging from 0.3mm to 6mm, with a maximum thickness of over 4.5mm, supporting diverse industrial applications. Backed by a 1-year warranty, our Industrial Printed Circuit Assembly service guarantees durability and performance for your critical projects.

Support and Services:

Our Industrial PCB Assembly product is backed by comprehensive technical support and services to ensure optimal performance and reliability. We provide expert assistance throughout the entire lifecycle of your PCB assemblies, from design consultation and prototyping to manufacturing and post-production support.

Our technical support team is equipped to help troubleshoot any issues, offer guidance on best practices, and provide firmware and software updates as required. We also offer customization services to tailor the assemblies to your specific industrial applications, ensuring seamless integration and functionality.

Additionally, we provide thorough documentation, including user manuals, assembly guidelines, and maintenance instructions to help you maximize the efficiency and longevity of your PCB assemblies. Our commitment to quality and customer satisfaction means you receive timely and effective solutions to keep your operations running smoothly.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each PCB is securely placed in anti-static bags and cushioned with foam inserts to prevent any damage from shocks or vibrations.

The assemblies are then boxed in sturdy, double-walled cartons designed to withstand heavy handling and stacking. Clear labeling with handling instructions and product details is applied to each package for easy identification and safe transport.

For shipping, we partner with reliable carriers that offer tracking and timely delivery services. We provide options for expedited shipping and international freight to meet the diverse needs of our clients.

Upon dispatch, customers receive detailed shipment notifications including tracking numbers to monitor their order status until it arrives safely at the destination.

FAQ:

Q1: What types of PCBs can be assembled in your industrial PCB assembly service?

A1: We assemble a wide range of PCBs including single-sided, double-sided, and multi-layer boards, supporting various materials such as FR4, CEM-1, and flexible substrates.

Q2: What assembly technologies do you use for industrial PCB assembly?

A2: Our facility utilizes advanced SMT (Surface Mount Technology), through-hole assembly, and mixed technology processes to meet diverse project requirements with high precision and efficiency.

Q3: Can you handle both small and large volume PCB assembly orders?

A3: Yes, we cater to both prototype runs and high-volume production, ensuring consistent quality and timely delivery regardless of order size.

Q4: What quality control measures are implemented during the assembly process?

A4: We employ rigorous quality control procedures including automated optical inspection (AOI), X-ray inspection, and in-circuit testing (ICT) to ensure the reliability and performance of every assembled PCB.

Q5: Do you support lead-free and RoHS-compliant PCB assembly?

A5: Absolutely. Our assembly processes comply with RoHS standards and we provide lead-free soldering options to meet environmental and industry regulations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!