Product Description:

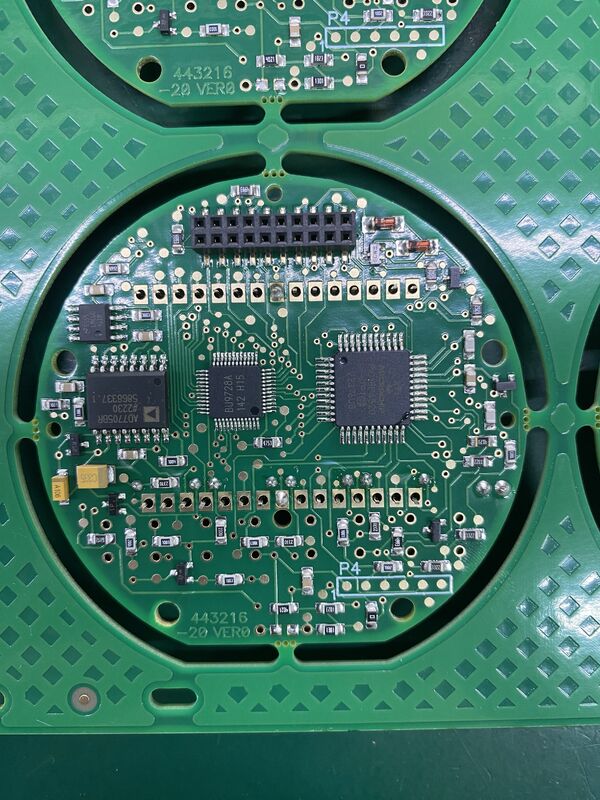

Our Industrial PCB Assembly product offers a comprehensive solution tailored to meet the demanding needs of modern industrial applications. Engineered with precision and reliability in mind, this product is designed to support a wide range of industrial electronics, ensuring optimal performance and durability in various operational environments. The Industrial Printed Circuit Assembly is an integral component for industries seeking robust and efficient electronic assemblies that can withstand rigorous conditions.

The product features an impressive thickness range from 0.3mm to 6mm, providing flexibility and adaptability to suit different industrial requirements. This range enables the assembly to handle diverse mechanical and thermal stresses, making it ideal for heavy-duty applications. Additionally, the PCB thickness varies from 0.2mm up to 3.2mm, allowing for customization according to specific technical demands. This precision in thickness selection ensures that the assembled PCBs maintain structural integrity while enhancing electrical performance.

Customization is a key aspect of our Industrial PCB Assembly service. Understanding that each industrial application may have unique specifications, we offer tailored solutions to meet those exact needs. Whether it involves specific dimensions, component arrangements, or specialized materials, our team works closely with clients to deliver assemblies that fit perfectly into their production lines. This commitment to customization is part of our broader Industrial Electronics Assembly Service, which aims to provide end-to-end support from design to final assembly.

Color options for the solder mask are diverse and vibrant, including Green, Red, Blue, Black, White, and Yellow. These color choices not only enhance the aesthetic appeal of the assembled PCBs but also serve practical purposes such as improved visibility for inspection and differentiation between various circuit boards in complex assemblies. The availability of multiple solder mask colors reflects our dedication to offering products that are both functional and visually distinct.

Our Industrial PCB Manufacturing Process is characterized by stringent quality control measures and advanced technological integration. Each stage of the manufacturing process, from material selection to final assembly, undergoes rigorous testing to ensure compliance with industry standards and customer specifications. This meticulous approach guarantees high reliability and longevity of the finished product, which is critical for industrial applications where failure is not an option.

To further instill confidence in our Industrial Printed Circuit Assembly, we provide a 1-year warranty. This warranty underscores our commitment to quality and customer satisfaction, assuring clients that the product will perform reliably over time. Should any issues arise within the warranty period, our support team is readily available to provide assistance and resolve concerns promptly.

In summary, our Industrial PCB Assembly product stands out as a robust, customizable, and high-quality solution for a variety of industrial electronics needs. With its adaptable thickness range, multiple solder mask color options, and a comprehensive 1-year warranty, it is designed to meet the stringent demands of industrial environments. Supported by a reliable Industrial Electronics Assembly Service and a meticulous Industrial PCB Manufacturing Process, this product ensures superior performance, durability, and customer satisfaction. Whether you are upgrading existing systems or developing new industrial electronic devices, our Industrial PCB Assembly product is the ideal choice for dependable and efficient circuit assembly.

Features:

- Product Name: Industrial PCB Assembly

- Soldermask Color Options: Green, Red, Blue, Black, White, Yellow

- Thickness Range: 0.3mm to 6mm

- Copper Weight: 4OZ

- Testing Service: 100% AOI, FCT, ICT Testing for quality assurance

- Silkscreen Color Options: White, Black, Yellow, and more

- Optimized for Industrial PCB Manufacturing Process to ensure high precision

- Advanced Industrial PCB Manufacturing Assembly techniques for reliable performance

- Comprehensive Industrial PCB Fabrication Assembly to meet diverse industrial requirements

Technical Parameters:

| Min Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| Max PCB Size |

600*1200mm |

| Customized |

Yes |

| Silkscreen Color |

White, Black, Yellow, Etc. |

| Soldermask Color |

Green, Red, Blue, Black, White, Yellow |

| Base Material |

FR4 |

| Impedance Control |

Yes |

| Copper |

4OZ |

| Testing Service |

100% AOI, FCT, ICT Testing |

| Max Thickness |

T > 4.5mm |

Applications:

Industrial PCB Assembly products play a crucial role in a wide range of industrial electronics applications, offering reliable and precise solutions tailored for OEM electronics manufacturers. These products are designed to meet the stringent requirements of industrial environments where durability, performance, and accuracy are paramount. With a PCB thickness range of 0.2-3.2mm and the capability to handle maximum thicknesses exceeding 4.5mm, these assemblies provide flexibility and robustness for various industrial applications.

One of the primary application occasions for Industrial PCB Assembly is in the manufacturing of complex industrial electronic devices that require precise impedance control. This feature ensures signal integrity and reduces electromagnetic interference, which is essential for high-frequency and high-speed electronic circuits used in automation systems, control panels, and machinery. The ability to maintain strict impedance control sets these assemblies apart, making them ideal for mission-critical industrial electronics.

Industrial Printed Circuit Board Assembly is also extensively used in sectors such as automotive electronics, aerospace equipment, power management systems, and heavy machinery controls. These scenarios demand high reliability and consistent performance, which is guaranteed through comprehensive testing services including 100% Automated Optical Inspection (AOI), Functional Circuit Testing (FCT), and In-Circuit Testing (ICT). Such rigorous testing ensures that each PCB assembly meets quality standards and performs flawlessly in challenging industrial environments.

Furthermore, the Industrial Electronics Assembly Service provided with these products supports OEM clients with customized solutions, adapting to unique design specifications and production volumes. Whether it is a prototype development or mass production, the service encompasses everything from component sourcing to final assembly, ensuring seamless integration into the client’s industrial products.

In summary, Industrial PCB Assembly Solutions cater to a broad spectrum of industrial applications where reliability, precision, and customization are critical. From controlling impedance to supporting thick PCB designs and providing exhaustive testing, these assemblies form the backbone of modern industrial electronics manufacturing. They empower OEM electronics manufacturers to develop high-quality, durable, and efficient electronic systems suitable for various industrial scenarios.

Customization:

Our Industrial PCB Fabrication Assembly services offer comprehensive product customization to meet the specific needs of your projects. We use high-quality FR4 as the base material, ensuring durability and reliability for industrial applications. Customers can choose from a variety of soldermask colors including Green, Red, Blue, Black, White, and Yellow to suit their design requirements.

With a maximum PCB size of 600*1200mm, our Industrial Circuit Board Assembly capabilities accommodate large and complex boards. We provide precise impedance control to guarantee optimal electrical performance and signal integrity in your industrial PCB fabrication assembly.

Additionally, we offer customizable silkscreen colors such as White, Black, Yellow, and other options to enhance the visibility and aesthetics of your circuit boards. Trust our Industrial PCB Fabrication Assembly services for tailored solutions that deliver high-quality, reliable, and efficient circuit board assemblies.

Support and Services:

Our Industrial PCB Assembly product is supported by a dedicated technical support team committed to ensuring optimal performance and reliability. We offer comprehensive services including design consultation, assembly process optimization, and quality assurance testing to meet your specific industrial requirements.

Our experts provide guidance on component selection, soldering techniques, and compliance with industry standards to enhance the durability and functionality of your assembled PCBs. We also offer troubleshooting assistance and repair services to minimize downtime and maintain production efficiency.

In addition, we provide custom prototyping and small to large volume production runs, with rigorous inspection protocols such as Automated Optical Inspection (AOI) and X-Ray analysis to guarantee the highest quality standards.

Our commitment to excellence ensures that your industrial PCB assemblies deliver consistent performance in demanding environments, supported by ongoing technical advice and post-production support tailored to your operational needs.

Packing and Shipping:

Our Industrial PCB Assembly products are packaged with the utmost care to ensure protection during transit. Each assembled PCB is placed in anti-static bags to prevent electrostatic discharge damage. The boards are then securely cushioned with foam inserts or bubble wrap to avoid physical damage.

For shipping, the packaged PCBs are placed in sturdy, double-walled corrugated cardboard boxes to provide structural strength. Multiple layers of protection are applied depending on the quantity and fragility of the order. All packages are clearly labeled with handling instructions such as “Fragile” and “Handle with Care.”

We partner with reliable freight and courier services to ensure timely and safe delivery. Tracking information is provided for all shipments, allowing customers to monitor their order status in real time.

Special packaging options are available upon request for customized protection or compliance with specific shipping regulations. Our goal is to deliver Industrial PCB Assemblies that arrive in perfect condition and ready for immediate use.

FAQ:

Q1: What types of PCBs can be assembled with your Industrial PCB Assembly service?

A1: Our Industrial PCB Assembly service supports a wide range of PCB types including single-sided, double-sided, and multi-layer boards. We can handle rigid, flexible, and rigid-flex PCBs to meet diverse industrial requirements.

Q2: What assembly technologies do you use for Industrial PCB Assembly?

A2: We utilize advanced assembly technologies such as Surface Mount Technology (SMT), Through-Hole Technology (THT), and Mixed Technology to ensure high precision and reliability in the assembled PCBs.

Q3: What is the typical turnaround time for Industrial PCB Assembly orders?

A3: The turnaround time depends on the complexity and volume of the order. Generally, standard orders are completed within 7 to 14 business days. We also offer expedited services for urgent projects.

Q4: Can you handle component sourcing for the PCB assembly?

A4: Yes, we provide comprehensive component sourcing services. We work with trusted suppliers to procure high-quality components, ensuring compliance with industry standards and availability for your project.

Q5: What quality control measures are implemented during the PCB assembly process?

A5: Our Industrial PCB Assembly process includes multiple quality control steps such as automated optical inspection (AOI), X-ray inspection for solder joint integrity, in-circuit testing (ICT), and functional testing to guarantee the highest quality and performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!