Product Description:

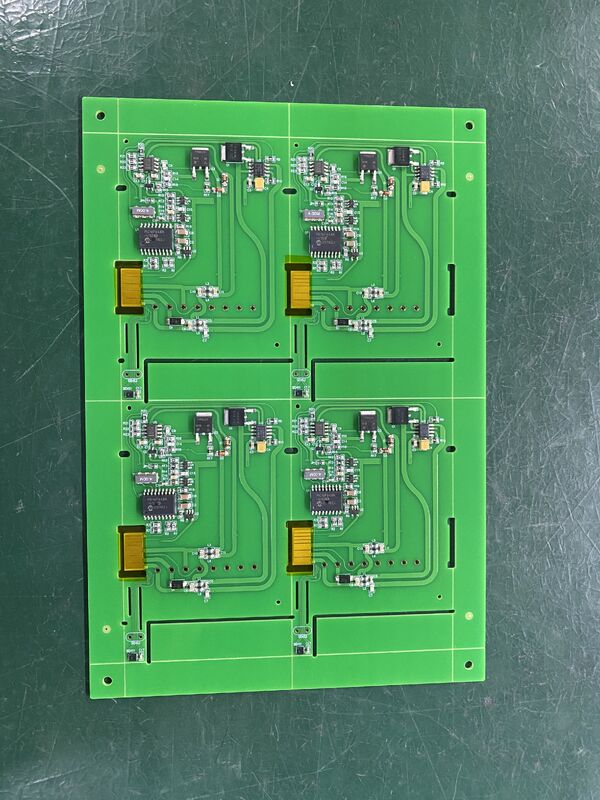

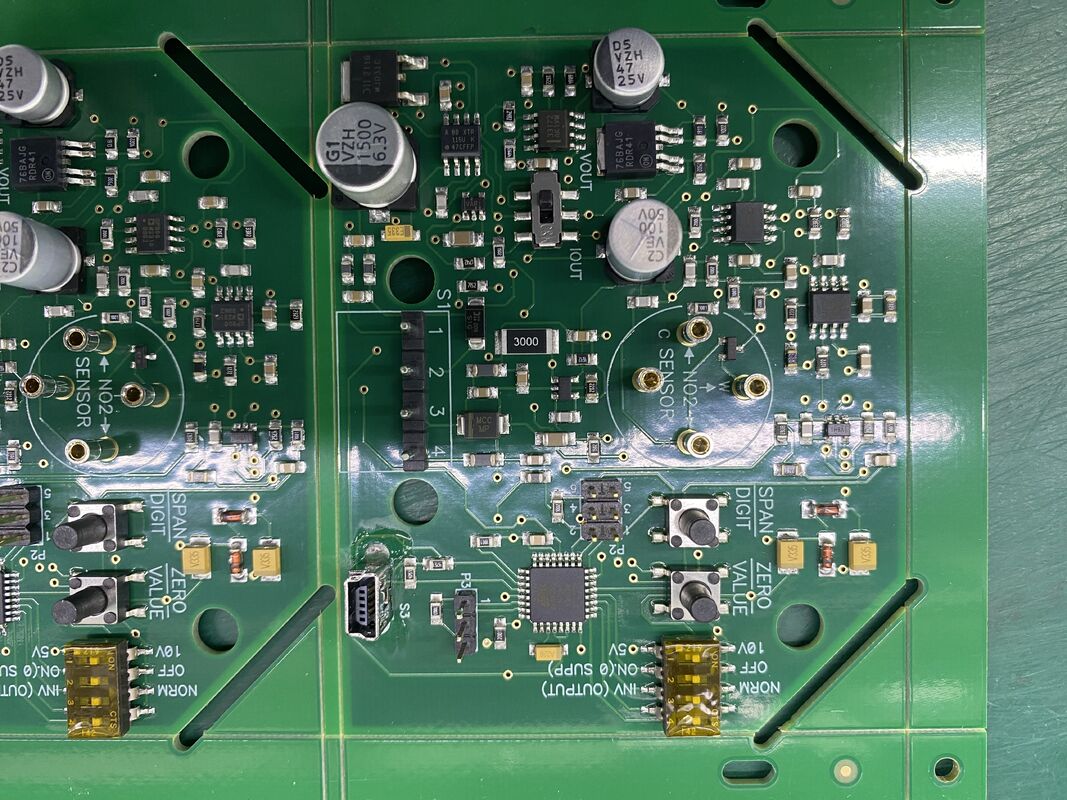

The Industrial PCB Assembly product is a highly advanced solution designed to meet the rigorous demands of modern electronic manufacturing. This product is engineered with precise impedance control, ensuring optimal signal integrity and performance across complex circuits. Impedance control is critical in high-speed and high-frequency applications, where maintaining consistent electrical characteristics is essential to avoid signal loss and interference. By incorporating impedance control, this Industrial PCB Assembly guarantees reliable operation in a wide range of industrial applications, making it an indispensable component for cutting-edge electronic devices.

One of the standout features of this product is its capability to handle a minimum ball space with a pitch ranging from 0.3mm to less than 0.5mm. This fine pitch specification allows for the assembly of densely packed components, enabling higher circuit complexity and greater functionality in a compact form factor. Such precision is crucial in industries where space constraints and performance requirements are paramount, including telecommunications, automotive electronics, and aerospace systems. The ability to manage this fine pitch reliably demonstrates the advanced capabilities of the Industrial Printed Circuit Board Assembly process.

The copper thickness used in this Industrial PCB Assembly is 4OZ, which provides excellent conductivity and current-carrying capacity. Thicker copper layers are beneficial for applications requiring enhanced thermal management and power handling. With 4OZ copper, the PCB can support higher current loads without overheating, ensuring durability and long-term stability in demanding industrial environments. This attribute also contributes to the robustness of the PCB, making it suitable for heavy-duty applications that require superior electrical performance and mechanical strength.

Customization options for silkscreen colors include white, black, yellow, and other colors, allowing for clear and durable markings on the PCB surface. Silkscreen plays a vital role in the Industrial PCB Manufacturing Process by providing essential information such as component designators, logos, and assembly instructions. The availability of multiple silkscreen color options enhances the visual distinction and readability, which is particularly useful during assembly, testing, and maintenance stages. This flexibility in silkscreen color selection reflects the product’s adaptability to various industrial requirements and aesthetic preferences.

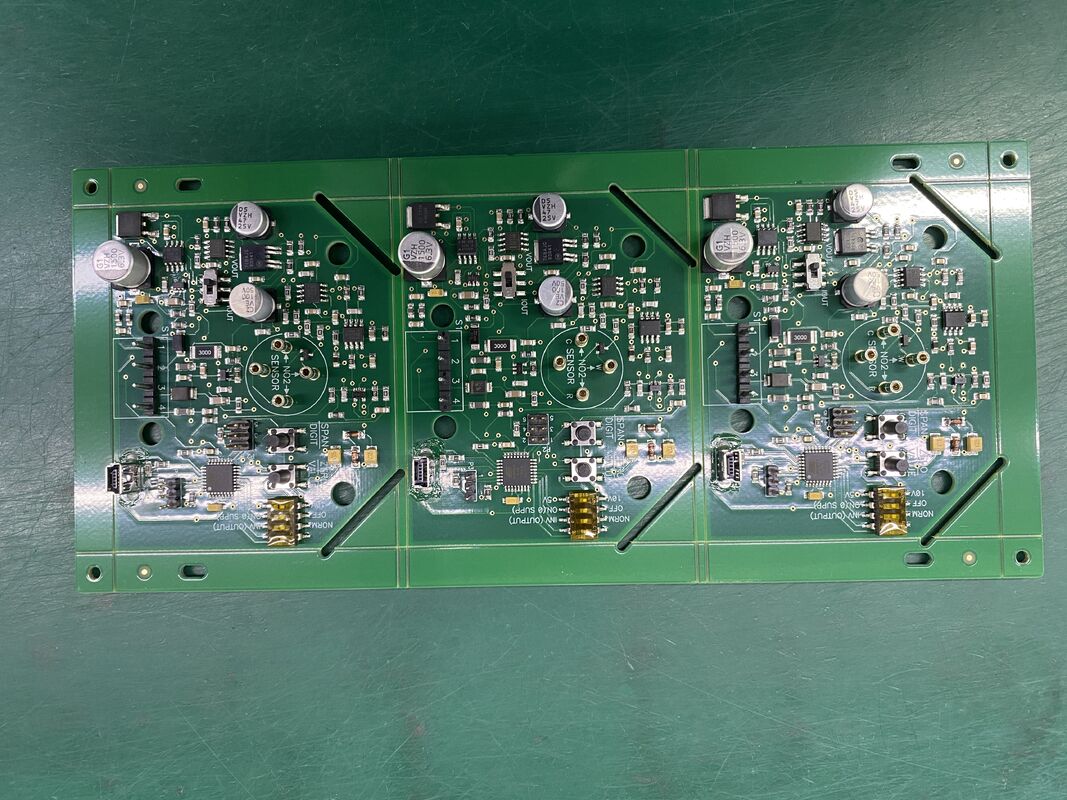

The maximum PCB size supported by this Industrial PCB Assembly product is an impressive 600mm by 1200mm. This large form factor capability accommodates extensive and complex circuit designs, making it ideal for industrial applications that demand high-density and large-scale PCBs. Whether used in industrial control systems, large communication devices, or sophisticated instrumentation, the ability to manufacture and assemble PCBs of this size expands the possibilities for innovation and functionality. The size capacity also underscores the advanced Industrial PCB Manufacturing Process employed, which is capable of handling large panels without compromising quality or precision.

In summary, this Industrial PCB Assembly product exemplifies excellence in the Industrial PCB Manufacturing Process by combining critical features such as impedance control, fine pitch ball spacing, thick copper layers, customizable silkscreen colors, and support for large PCB sizes. These attributes collectively ensure superior electrical performance, reliability, and versatility, making the product well-suited for a broad spectrum of industrial applications. Whether for high-speed data transmission, power-intensive devices, or complex multi-layer circuits, this Industrial Printed Circuit Board Assembly provides a robust and efficient foundation for cutting-edge electronic solutions.

Leveraging advanced techniques in the Industrial PCB Manufacturing Process, this product guarantees consistency, precision, and high quality in every unit produced. Its design and manufacturing standards meet stringent industrial requirements, ensuring that it performs reliably even under harsh operating conditions. As industries continue to evolve and integrate more sophisticated electronic systems, this Industrial PCB Assembly stands out as a dependable and innovative choice for manufacturers aiming to deliver top-tier products to the market.

Features:

- Product Name: Industrial PCB Assembly

- Soldermask Color Options: Green, Red, Blue, Black, White, Yellow

- Maximum PCB Size: 600*1200mm

- Material Types: FR4, CEM-1, CEM-3

- Thickness Range: 0.3mm to 6mm

- Warranty: 1 Year

- Provides reliable Industrial Electronics Assembly Service

- Expertise in Industrial PCB Fabrication Assembly

- Comprehensive Industrial Electronics Assembly Service for diverse applications

Technical Parameters:

| Thickness |

0.3mm - 6mm |

| Minimum Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| Testing Service |

100% AOI, FCT, ICT Testing |

| Impedance Control |

Yes |

| Maximum Thickness |

T > 4.5mm |

| PCB Thickness |

0.2mm - 3.2mm |

| Customized |

Yes |

| Maximum PCB Size |

600 x 1200mm |

| Base Material |

FR4 |

| Soldermask Color |

Green, Red, Blue, Black, White, Yellow |

Applications:

Industrial PCB Assembly plays a crucial role in various industrial electronic applications, offering reliable and high-quality solutions for complex circuit requirements. With advanced features such as impedance control, 4OZ copper thickness, and a maximum PCB size of 600*1200mm, this product is designed to meet the stringent demands of Industrial Electronic Circuit Assembly. These attributes ensure enhanced signal integrity, durability, and performance in harsh industrial environments, making it ideal for critical electronic systems.

The Industrial Electronic Board Assembly process is supported by rigorous 100% AOI (Automated Optical Inspection), FCT (Functional Circuit Testing), and ICT (In-Circuit Testing) services. These comprehensive testing methodologies guarantee that each PCB assembly meets exacting quality standards, minimizing defects and ensuring consistent functionality. Such thorough testing is essential in industries where reliability and precision are paramount, such as automation, machinery control, and power management systems.

Customization is another key advantage of this Industrial Electronics Assembly Service. Whether the project requires specific impedance control parameters, unique copper thickness, or specialized PCB dimensions up to 600*1200mm, the service can tailor the assembly to exact customer specifications. This flexibility makes it suitable for a broad range of industrial applications, including robotics, instrumentation, and heavy equipment electronics.

Typical application occasions for Industrial PCB Assembly include factory automation systems, industrial control panels, energy management devices, and communication equipment within manufacturing plants. The robust design and meticulous testing ensure that the assembled boards can withstand extreme conditions such as high temperature, vibration, and electrical noise commonly found in industrial settings.

In summary, the Industrial Electronic Circuit Assembly, Industrial Electronic Board Assembly, and Industrial Electronics Assembly Service offer comprehensive solutions for industries that demand high reliability, customization, and superior electrical performance. The combination of impedance control, 4OZ copper, extensive testing, and large PCB size capacity makes this product an excellent choice for complex and mission-critical industrial electronic applications.

Customization:

Our Industrial PCB Assembly product offers comprehensive customization services tailored to meet the rigorous demands of Industrial PCB Manufacturing Assembly. We provide 100% AOI, FCT, and ICT testing services to ensure the highest quality and reliability of every board.

We support a wide range of thicknesses from 0.3mm up to 6mm, including a maximum thickness capability of over 4.5mm (T>4.5mm), accommodating diverse industrial applications. Our soldermask colors include Green, Red, Blue, Black, White, and Yellow, allowing for versatile design options.

Using premium materials such as FR4, CEM-1, and CEM-3, our Industrial Electronics Assembly Service guarantees sturdy and durable printed circuit boards. Our Industrial Printed Circuit Assembly process is optimized for performance and longevity, making it ideal for demanding industrial environments.

Support and Services:

Our Industrial PCB Assembly product is backed by comprehensive technical support and professional services to ensure optimal performance and reliability. We offer expert assistance throughout the entire product lifecycle, including design consultation, assembly process optimization, and troubleshooting.

Our technical support team is available to help with installation guidance, firmware updates, and integration with existing systems. We also provide detailed documentation and resources to facilitate smooth implementation and maintenance.

In addition, we offer customized training sessions and on-site support to address specific requirements and enhance your team's technical capabilities. Our commitment is to deliver timely and effective solutions to minimize downtime and maximize productivity.

For any technical inquiries or service requests, our dedicated support professionals are ready to assist you to ensure your Industrial PCB Assembly operates at peak efficiency.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each assembly is placed in anti-static bags to prevent electrostatic discharge and then cushioned with foam inserts inside sturdy, corrugated cardboard boxes. This packaging method safeguards the components from physical damage, moisture, and environmental contaminants.

For shipping, we offer multiple options tailored to your delivery needs, including standard ground, expedited air freight, and international shipping. All shipments are tracked and insured to provide peace of mind. Additionally, we comply with all regulatory requirements for electronics transportation to ensure safe and timely delivery of your Industrial PCB Assembly products.

FAQ:

Q1: What types of components can be assembled on the Industrial PCB Assembly?

A1: Our Industrial PCB Assembly supports a wide range of components including through-hole, surface-mount devices (SMD), and mixed technology components to meet diverse industrial application needs.

Q2: What is the typical production lead time for Industrial PCB Assembly orders?

A2: The standard lead time is usually between 7 to 15 business days, depending on the complexity and quantity of the order. Expedited services are available upon request.

Q3: What quality standards do you follow for Industrial PCB Assembly?

A3: We adhere to strict quality control processes compliant with IPC-A-610 standards to ensure high reliability and performance in industrial environments.

Q4: Can you handle high-volume manufacturing for Industrial PCB Assembly?

A4: Yes, we have the capacity and advanced equipment to manage both low-volume prototypes and high-volume production runs efficiently.

Q5: Do you provide testing services for assembled PCBs?

A5: Absolutely. We offer comprehensive testing options including AOI (Automated Optical Inspection), functional testing, and in-circuit testing to ensure the assembly meets all specifications.

Quality Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!