Product Description:

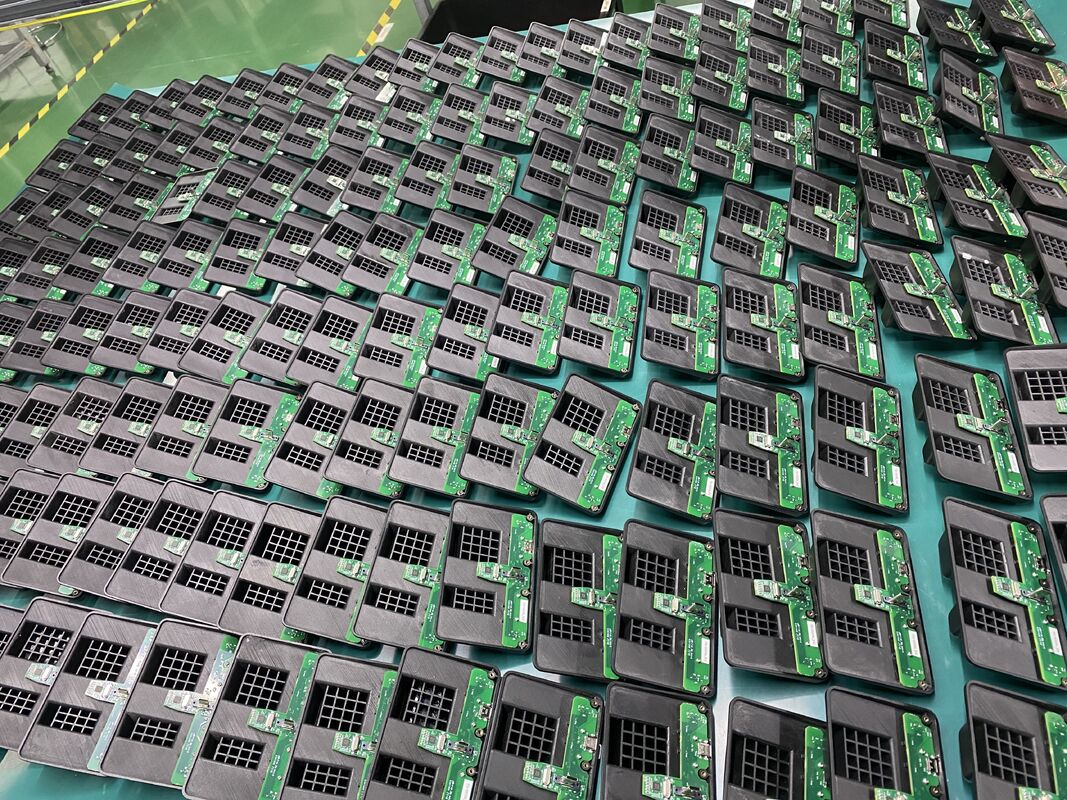

Our Industrial PCB Assembly product is expertly designed to meet the rigorous demands of modern electronic manufacturing, providing a reliable and high-quality solution for a wide range of industrial applications. Utilizing FR4 as the base material, this assembly offers exceptional durability and stability, making it an ideal choice for OEM electronics where performance and consistency are paramount. The FR4 substrate is well-known for its excellent mechanical strength and excellent electrical insulation properties, ensuring long-lasting and dependable operation in various industrial environments.

The Industrial PCB Fabrication Assembly is engineered with a thickness range from 0.2mm up to 3.2mm, allowing for versatile application across different device specifications. This flexibility ensures that the PCB can be tailored precisely to the mechanical and electrical requirements of the target equipment, providing an optimal fit and function. Additionally, the copper layer utilized in the assembly boasts a robust 4OZ thickness, which enhances the electrical conductivity and thermal management of the board. This thicker copper layer not only supports higher current loads but also improves heat dissipation, essential for maintaining performance and reliability in demanding industrial electronic circuit assembly tasks.

Beyond the base material and copper specifications, our Industrial PCB Assembly product supports an overall thickness range from 0.3mm to 6mm. This broad thickness spectrum accommodates various industrial designs, from ultra-thin, compact electronics to more robust, heavy-duty circuit boards. Such adaptability is crucial for OEM manufacturers who require precision and customization to meet their unique product demands. The comprehensive thickness options ensure that the PCB can be integrated seamlessly into diverse electronic assemblies, enhancing both structural integrity and functional performance.

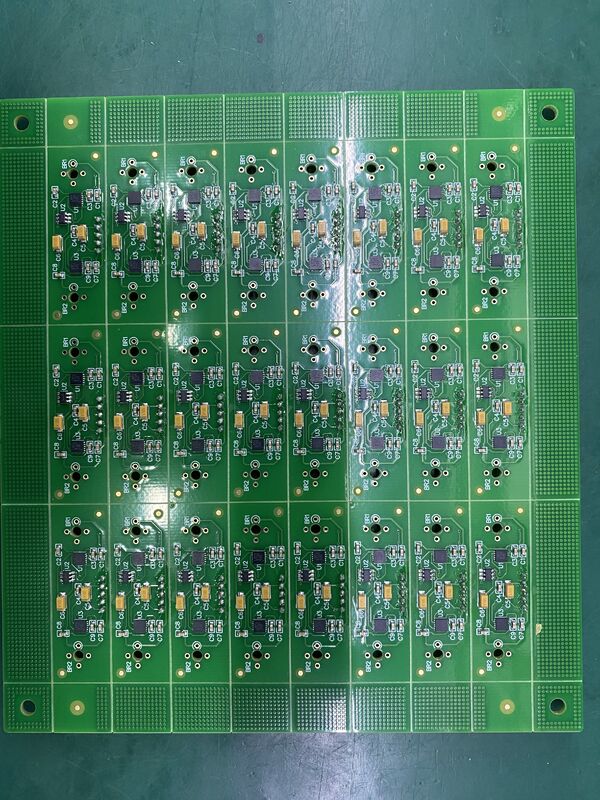

In the realm of Industrial Electronic Circuit Assembly, our product stands out by offering superior fabrication and assembly quality. Each PCB undergoes stringent quality control processes to verify dimensional accuracy, electrical continuity, and solderability, thereby minimizing defects and ensuring high yield rates in production. This rigorous quality assurance makes the Industrial PCB Fabrication Assembly a trusted component in critical industrial applications, where reliability and efficiency are non-negotiable.

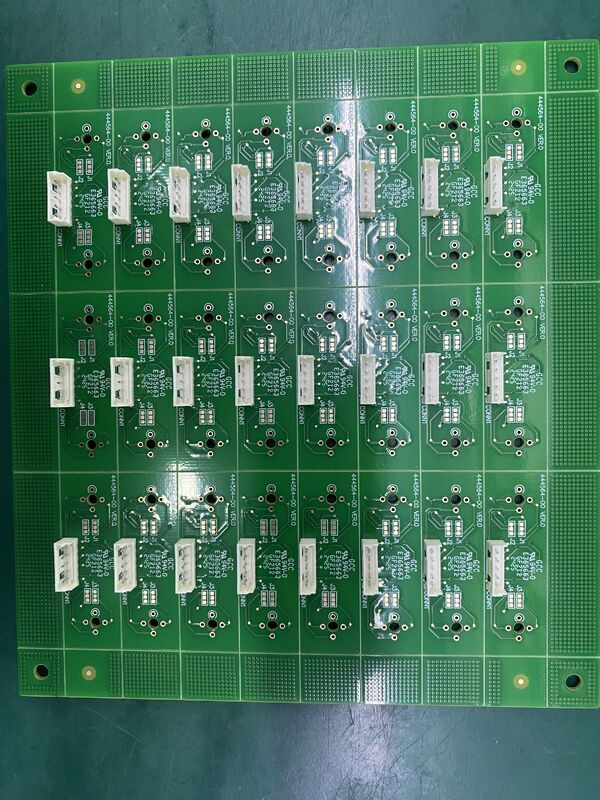

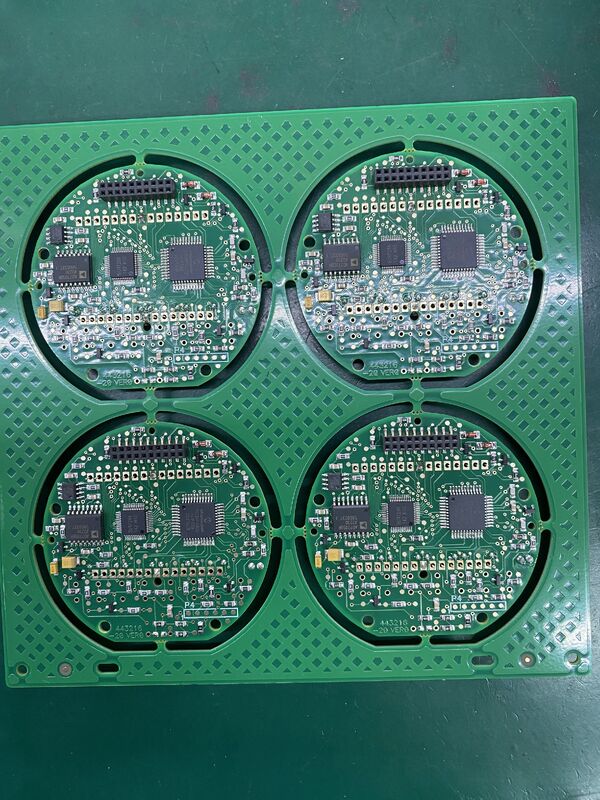

The Industrial PCB Fabrication Assembly is particularly suited for OEM electronics manufacturers who demand not only high-quality materials but also precision engineering to support complex circuitry and high-density component placement. Our assembly process supports advanced manufacturing techniques, including surface mount technology (SMT) and through-hole assembly, enabling the production of intricate industrial electronic circuit assemblies with excellent signal integrity and minimal electromagnetic interference.

Furthermore, the use of FR4 as the base material provides excellent thermal resistance and flame retardancy, meeting industry standards and safety regulations. This makes the Industrial PCB Assembly a dependable choice for applications in harsh industrial environments, where exposure to heat, chemicals, and mechanical stress is common. The combination of high-quality FR4, robust 4OZ copper layers, and customizable thickness parameters makes this product a versatile and resilient solution for various industrial electronic needs.

In summary, our Industrial PCB Assembly product combines premium FR4 base material, substantial copper thickness, and a flexible range of board thicknesses to deliver a reliable and high-performance solution for industrial electronic circuit assembly. Whether for OEM electronics production or complex industrial applications, this product ensures exceptional durability, electrical performance, and manufacturing precision. Choosing our Industrial PCB Fabrication Assembly means investing in quality, reliability, and innovation that supports the future of industrial electronics manufacturing.

Features:

- Product Name: Industrial PCB Assembly

- Thickness Range: 0.2-3.2mm

- Impedance Control: Yes, ensuring signal integrity

- Base Material: FR4 for durability and reliability

- Customization: Fully customized to meet specific industrial requirements

- Testing Service: 100% AOI, FCT, and ICT testing for quality assurance

- Specialized in Industrial Printed Circuit Assembly

- Offers comprehensive Industrial Electronics Assembly Service

- Reliable Industrial Electronics Assembly Service tailored for various applications

Technical Parameters:

| Thickness |

0.3mm - 6mm |

| Customized |

Yes |

| Base Material |

FR4 |

| Soldermask Color |

Green, Red, Blue, Black, White, Yellow |

| Min Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| Max Thickness |

T > 4.5mm |

| Max PCB Size |

600*1200mm |

| Testing Service |

100% AOI, FCT, ICT Testing |

| Warranty |

1 Year |

| Usage |

OEM Electronics |

Applications:

The Industrial Printed Circuit Assembly (PCA) is a crucial component in various industrial applications, designed to meet the demanding requirements of modern electronic devices. With a robust construction using high-quality materials such as FR4, CEM-1, and CEM-3, this product ensures superior durability and performance. The 4OZ copper thickness provides excellent electrical conductivity and heat dissipation, making it ideal for heavy-duty industrial environments where reliability is paramount. Additionally, the maximum board thickness of over 4.5mm enhances mechanical strength, allowing it to withstand harsh conditions and mechanical stress.

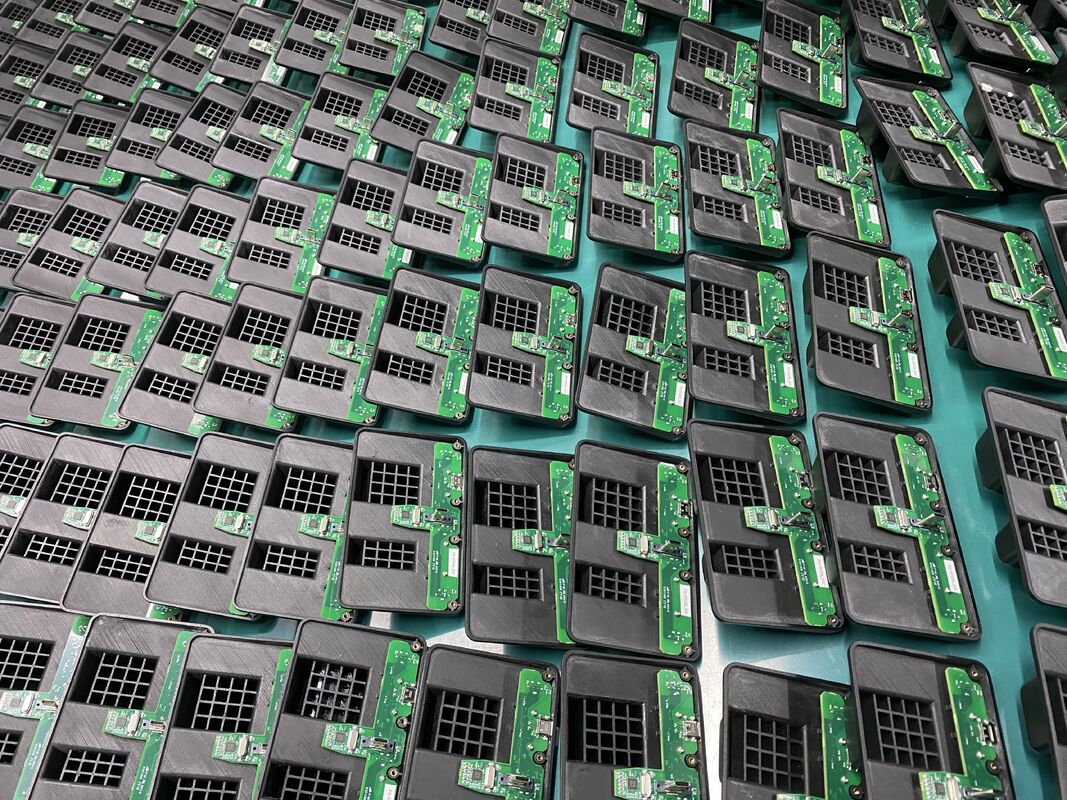

One of the primary application occasions for Industrial Printed Circuit Assembly is in OEM electronics manufacturing. Many original equipment manufacturers rely on Industrial Circuit Board Assembly to integrate complex electronic systems in machinery, automation equipment, and control systems. The precision and quality control involved in the Industrial PCB Manufacturing Process guarantee that each board meets rigorous specifications, reducing downtime and improving product lifespan.

In industrial automation and control systems, these circuit boards are extensively used to support sensors, actuators, and communication modules. Their reliability ensures seamless operation of conveyor systems, robotic arms, and process control units, which are essential for modern manufacturing plants. The 1-year warranty offered with the product provides customers with confidence in its long-term performance and durability.

Furthermore, Industrial Printed Circuit Assembly plays a vital role in power management and distribution systems. The enhanced copper thickness and sturdy materials allow the board to handle higher currents and voltages safely, making it suitable for power converters, inverters, and industrial power supplies. This makes it an excellent choice for energy management solutions in factories and large-scale industrial facilities.

Other scenarios involve the use of these assemblies in telecommunications infrastructure, medical equipment, and transportation systems, where consistent performance and reliability are critical. The Industrial PCB Manufacturing Process incorporates advanced techniques that ensure precision, reducing the risk of failure in mission-critical applications.

In summary, the Industrial Printed Circuit Assembly is an essential component for various industrial sectors requiring high-performance, reliable, and durable circuit boards. Its use in OEM electronics, automation, power management, and other industrial applications demonstrates its versatility and critical role in advancing industrial technology.

Customization:

Our Industrial PCB Fabrication Assembly offers comprehensive product customization services tailored to meet your specific requirements. We provide 100% AOI, FCT, and ICT testing services to ensure the highest quality and reliability of every Industrial Printed Circuit Board Assembly we produce. With the capability to handle a maximum PCB size of 600*1200mm and thickness greater than 4.5mm, we accommodate a wide range of industrial applications. Our services include precise impedance control to guarantee optimal electrical performance. Whether you need standard or fully customized Industrial Printed Circuit Board Assembly solutions, our expert team is equipped to deliver exceptional results that meet your exact specifications.

Support and Services:

Our Industrial PCB Assembly product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide expert guidance throughout the entire lifecycle of the product, from initial design consultation to post-installation maintenance.

Our technical support team is equipped to assist with troubleshooting, configuration, and integration of the PCB assemblies into your industrial systems. We offer detailed documentation, including user manuals, assembly instructions, and application notes to facilitate smooth implementation.

In addition to remote support, we provide on-site services such as installation assistance, system calibration, and training for your technical staff. Our maintenance services include regular inspections, firmware updates, and repair solutions to minimize downtime and extend the lifespan of your PCB assemblies.

We are committed to delivering prompt and effective support to address any issues that may arise, ensuring your operations remain efficient and reliable. Our goal is to partner with you to maximize the value and performance of your Industrial PCB Assembly investment.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each assembled PCB is placed in anti-static packaging to prevent electrostatic discharge damage. The PCBs are then cushioned with foam or bubble wrap and securely packed in sturdy, double-walled cardboard boxes to withstand handling and shipping stresses.

For shipping, we offer multiple options including standard ground, expedited, and overnight delivery services. All shipments are tracked and insured to guarantee safe and timely arrival. We also provide custom packaging solutions upon request to meet specific industrial requirements.

Our commitment to quality packaging and reliable shipping ensures that your Industrial PCB Assemblies arrive in perfect condition, ready for immediate use in your production line or project.

FAQ:

Q1: What types of components can be assembled on Industrial PCBs?

A1: Our Industrial PCB Assembly services support a wide range of components including through-hole, surface-mount devices (SMD), connectors, and high-density interconnect parts to meet various industrial applications.

Q2: What industries do you serve with your Industrial PCB Assembly?

A2: We provide PCB assembly solutions primarily for industries such as automotive, aerospace, telecommunications, medical devices, and industrial automation.

Q3: What is the typical turnaround time for Industrial PCB Assembly orders?

A3: Depending on the complexity and quantity, standard lead times range from 7 to 15 business days. Expedited services are available upon request.

Q4: Do you offer testing and inspection services for assembled PCBs?

A4: Yes, we provide comprehensive testing options including AOI (Automated Optical Inspection), X-ray inspection, functional testing, and in-circuit testing to ensure high quality and reliability.

Q5: Can you handle both prototype and high-volume production runs?

A5: Absolutely. Our facilities are equipped to efficiently manage both small prototype batches and large-scale production runs with consistent quality control.

Assembly Process Flow

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!