Product Description:

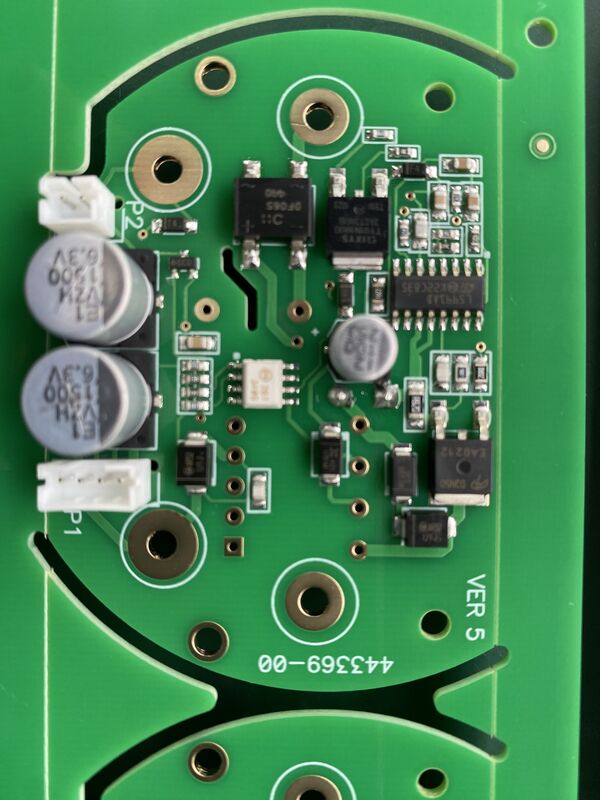

Our Industrial PCB Assembly product offers a comprehensive solution tailored for high-quality and reliable electronic manufacturing services. Designed to meet the rigorous demands of industrial applications, this product ensures optimal performance and durability, making it an ideal choice for OEM electronics. Leveraging advanced Industrial Electronics Assembly Service techniques, we provide precise and efficient assembly that caters specifically to the complex requirements of industrial electronic systems.

The Industrial PCB Assembly utilizes a premium FR4 base material, known for its excellent mechanical strength and thermal resistance. This ensures that the printed circuit boards (PCBs) can withstand harsh operating environments typically encountered in industrial settings. With a robust 4OZ copper layer, the boards offer superior electrical conductivity and enhanced current-carrying capacity, which is critical for industrial electronic devices that operate under high power loads.

One of the standout features of our Industrial PCB Assembly is the variety of soldermask colors available. Customers can choose from Green, Red, Blue, Black, White, and Yellow soldermasks, allowing for both functional and aesthetic customization. The soldermask not only protects the copper traces from oxidation and short circuits but also improves the overall reliability of the PCB. Complementing the soldermask options, the silkscreen layer can be customized in White, Black, Yellow, and other colors, providing clear and precise component labeling for easy identification and assembly. This attention to detail enhances the efficiency of the Industrial Electronic Board Assembly process and helps in troubleshooting and maintenance.

Our Industrial PCB Manufacturing Assembly service is designed to support large-scale production runs as well as prototype development. We employ state-of-the-art machinery and quality control protocols to ensure every PCB meets stringent industrial standards. This includes automated optical inspection (AOI), X-ray inspection for solder joint integrity, and functional testing to guarantee the highest level of quality assurance. By integrating these processes within the Industrial Electronics Assembly Service, we deliver reliable and consistent results that clients can depend on for their critical industrial applications.

The versatility of our Industrial PCB Assembly extends to a wide range of OEM electronics, including control systems, automation equipment, power supplies, and communication devices. With our tailored Industrial Electronic Board Assembly capabilities, we ensure that each PCB assembly aligns perfectly with the specific requirements of the end product. This customization capability allows manufacturers to achieve optimal performance and longevity in their electronic devices, contributing to reduced downtime and increased operational efficiency.

In addition to the technical specifications and customization options, our Industrial PCB Manufacturing Assembly service emphasizes sustainability and cost-effectiveness. We optimize the production process to minimize waste and reduce material costs without compromising quality. This makes our Industrial PCB Assembly an attractive choice for manufacturers seeking to balance performance, reliability, and budget constraints.

In summary, our Industrial PCB Assembly product combines high-quality FR4 base material, 4OZ copper layers, and customizable silkscreen and soldermask colors to deliver superior industrial electronic boards. Supported by a robust Industrial Electronics Assembly Service and rigorous quality control measures, this product is engineered to meet the diverse needs of OEM electronics manufacturers. Whether for small-scale prototypes or large production volumes, our Industrial Electronic Board Assembly and Industrial PCB Manufacturing Assembly services provide dependable, efficient, and tailored solutions that enhance the performance and reliability of industrial electronic systems.

Features:

- Product Name: Industrial PCB Assembly

- Min Ball Space: 0.3mm ≤ Pitch < 0.5mm

- Base Material: FR4

- Max PCB Size: 600*1200mm

- Warranty: 1 Year

- Soldermask Color Options: Green, Red, Blue, Black, White, Yellow

- Designed for Industrial Printed Circuit Board Assembly applications

- Utilizes a precise Industrial PCB Manufacturing Process to ensure quality and reliability

- Ideal solution for various Industrial Printed Circuit Board Assembly needs

Technical Parameters:

| Warranty |

1 Year |

| Min Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| Base Material |

FR4 |

| Copper |

4OZ |

| Usage |

OEM Electronics |

| Thickness |

0.3mm - 6mm |

| PCB Thickness |

0.2mm - 3.2mm |

| Material |

FR4, CEM-1, CEM-3 |

| Impedance Control |

Yes |

| Soldermask Color |

Green, Red, Blue, Black, White, Yellow |

Applications:

The Industrial PCB Assembly product is designed to meet the rigorous demands of various industrial applications, making it an ideal choice for businesses seeking reliable and high-quality Industrial Circuit Board Assembly solutions. With a thickness range of 0.3mm to 6mm and a maximum thickness capability of over 4.5mm, this product accommodates a wide variety of industrial electronics requirements, ensuring durability and performance in harsh environments.

One of the key application occasions for this product is in heavy machinery and automation systems, where robust and precise Industrial Printed Circuit Assembly is essential for maintaining operational efficiency. The ability to handle large PCB sizes up to 600*1200mm allows it to support complex and large-scale industrial electronics assembly service projects, including control panels, manufacturing equipment, and power management systems.

Additionally, this Industrial Electronics Assembly Service caters to industries such as automotive manufacturing, aerospace, energy, and telecommunications. The flexibility in soldermask colors—available in green, red, blue, black, white, and yellow—enables customization to meet specific design and identification needs, while the silkscreen color options including white, black, yellow, and others provide clear labeling and functional markings for easier maintenance and troubleshooting.

In scenarios where reliability and precision are paramount, such as industrial robotics, medical instruments, and instrumentation devices, this Industrial PCB Assembly ensures consistent electrical performance and mechanical stability. Its advanced manufacturing capabilities support high-volume production runs as well as specialized prototype developments, making it suitable for both large enterprises and innovative startups.

Overall, the Industrial PCB Assembly product is versatile and robust, perfectly suited for a broad spectrum of industrial electronic applications. Whether used in production lines, testing equipment, or critical infrastructure, it delivers superior quality and functionality, supporting the evolving needs of modern industrial electronics assembly service and Industrial Printed Circuit Assembly projects.

Customization:

Our Industrial Printed Circuit Assembly services offer extensive product customization to meet your specific requirements. We provide a variety of soldermask colors including Green, Red, Blue, Black, White, and Yellow, allowing you to tailor the appearance and functionality of your PCB to your needs.

With Industrial PCB Manufacturing Assembly, you can choose from multiple silkscreen color options such as White, Black, Yellow, and more, ensuring clear labeling and enhanced readability on your electronic boards.

We accommodate a wide range of thicknesses to suit different applications, with PCB thickness options from 0.2mm to 3.2mm and overall board thickness ranging from 0.3mm to 6mm, providing flexibility in design and durability.

Our Industrial Electronic Board Assembly comes with a 1-year warranty, guaranteeing the quality and reliability of your customized PCBs. Trust us to deliver high-quality, tailored solutions for your industrial electronic assembly needs.

Support and Services:

Our Industrial PCB Assembly product comes with comprehensive technical support and services designed to ensure optimal performance and reliability. We offer expert consultation during the design and prototyping stages to help tailor the assembly process to your specific application requirements. Our team provides thorough testing and inspection services, including automated optical inspection (AOI) and functional testing, to guarantee product quality and adherence to industry standards.

Additionally, we deliver ongoing maintenance support and troubleshooting assistance to minimize downtime and extend the lifespan of your assemblies. Custom training sessions are available to equip your staff with the necessary skills for handling and maintaining the PCBs. We also provide documentation and firmware updates as part of our commitment to continuous improvement and customer satisfaction.

Choose our Industrial PCB Assembly services for a reliable partnership backed by technical expertise, meticulous quality control, and dedicated customer care throughout the product lifecycle.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each assembled PCB is placed in anti-static bags to prevent electrostatic discharge, then securely cushioned with foam or bubble wrap to avoid physical damage.

The protected PCBs are then placed in sturdy, appropriately sized cartons with additional padding to minimize movement. All packaging materials used are industrial-grade to withstand handling and environmental factors during shipping.

For shipping, we offer various options including express courier, freight, and pallet shipping depending on order size and destination. Each shipment is tracked and insured to guarantee safe and timely delivery to our customers.

Our packaging and shipping process is designed to maintain the quality and integrity of the Industrial PCB Assembly products from our facility to your doorstep.

FAQ:

Q: What types of components can be assembled on the Industrial PCB Assembly?

A: Our Industrial PCB Assembly supports a wide range of components including SMD (Surface Mount Devices), through-hole components, connectors, and complex multi-layer boards, ensuring compatibility with various industrial applications.

Q: What is the typical turnaround time for an Industrial PCB Assembly order?

A: The standard turnaround time is usually between 7 to 14 business days, depending on the complexity and quantity of the order. Expedited services are available for urgent projects.

Q: Can the Industrial PCB Assembly handle high-volume production runs?

A: Yes, our assembly lines are equipped to handle both small prototype batches and large-scale production runs, making it suitable for both testing and mass manufacturing in industrial environments.

Q: What quality control measures are implemented in the Industrial PCB Assembly process?

A: We employ rigorous quality control procedures including automated optical inspection (AOI), X-ray inspection, and functional testing to ensure each PCB assembly meets industry standards and customer specifications.

Q: Are custom PCB assembly services available for specialized industrial applications?

A: Absolutely. We offer customized assembly solutions tailored to specific industrial requirements, including custom soldering processes, conformal coating, and specialized packaging options.

Quality Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!