Product Description:

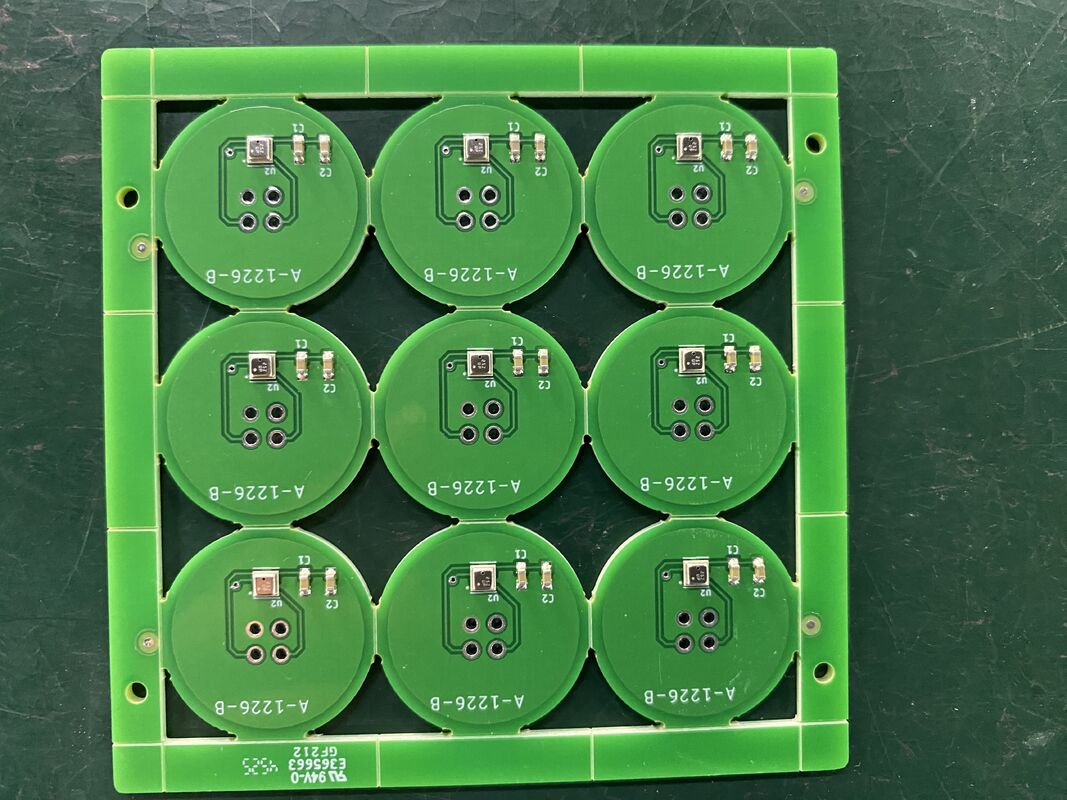

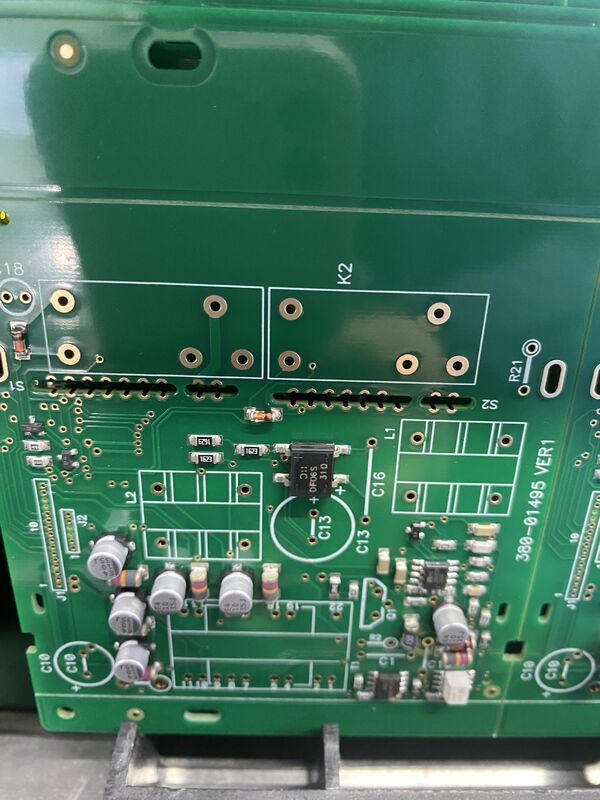

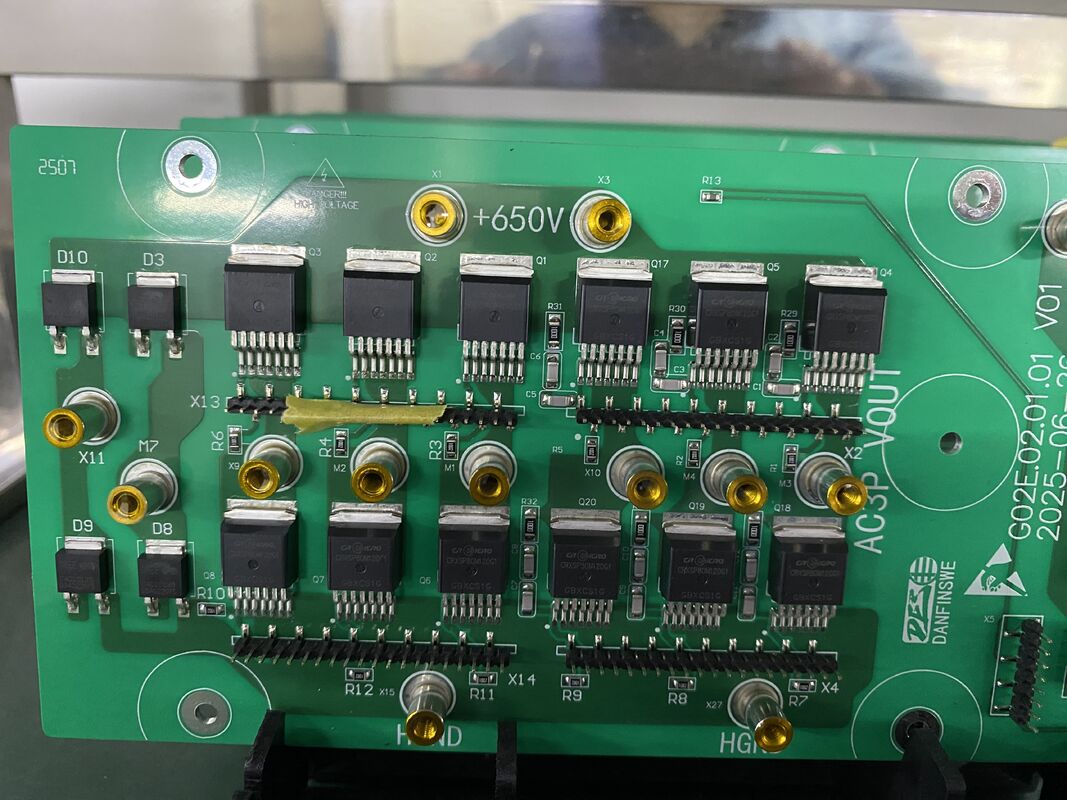

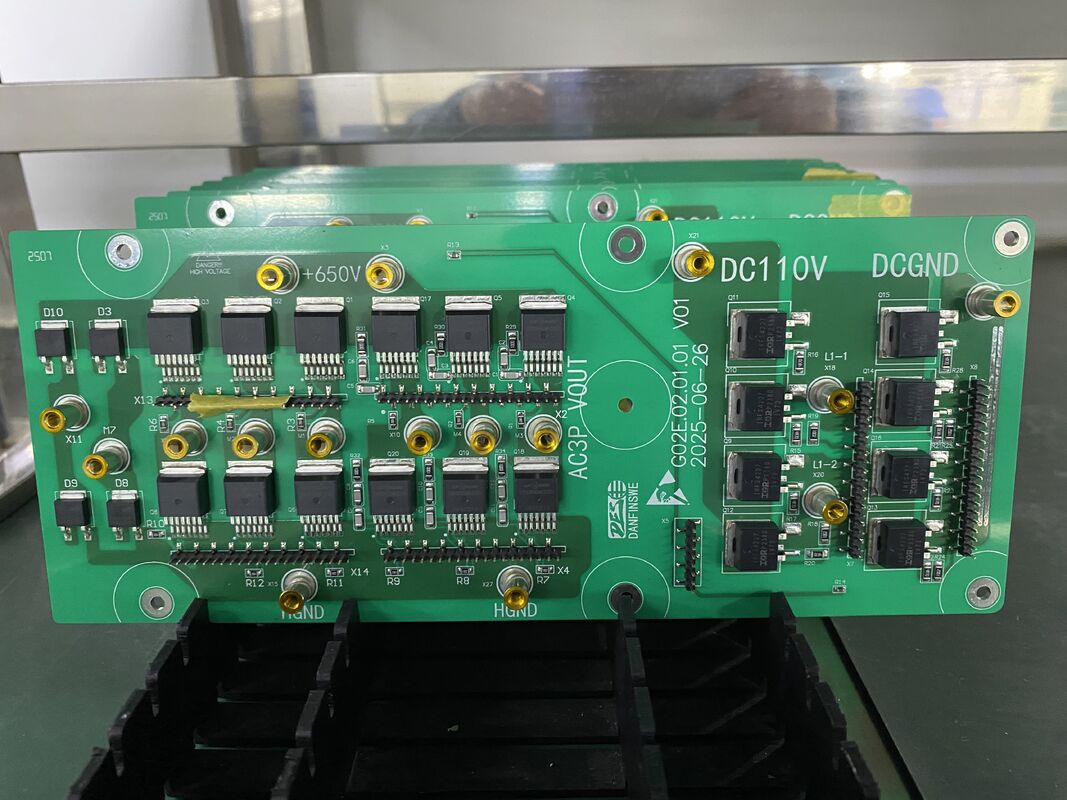

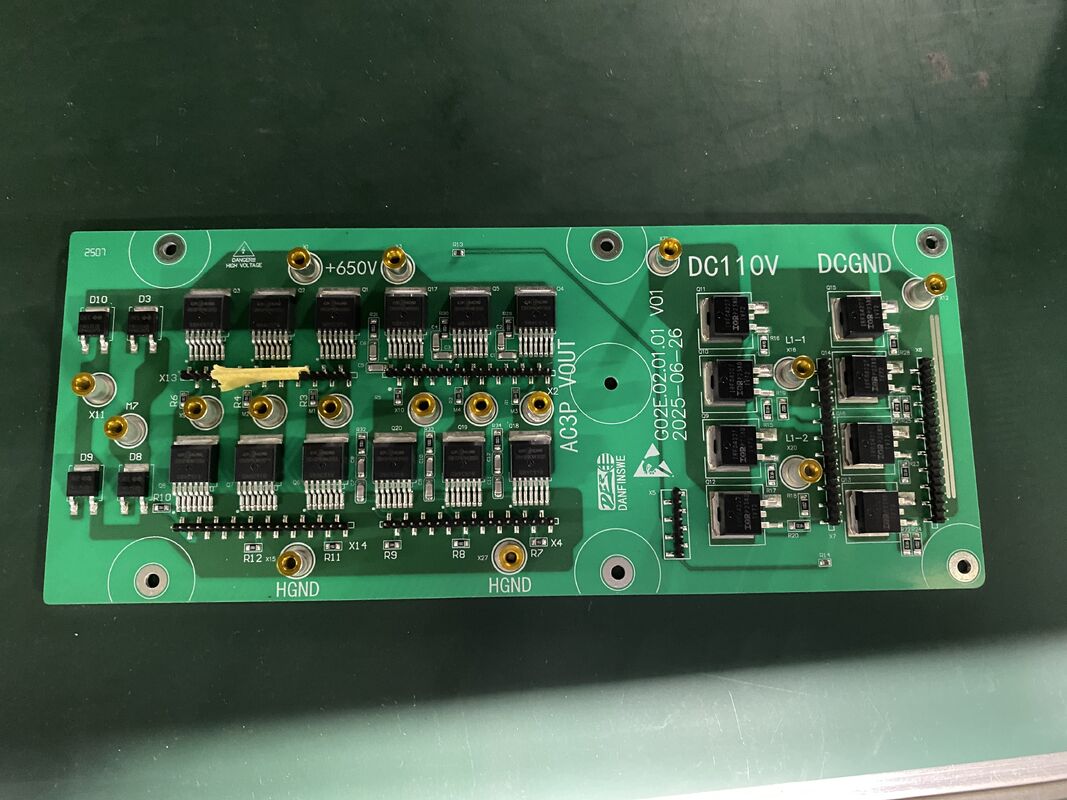

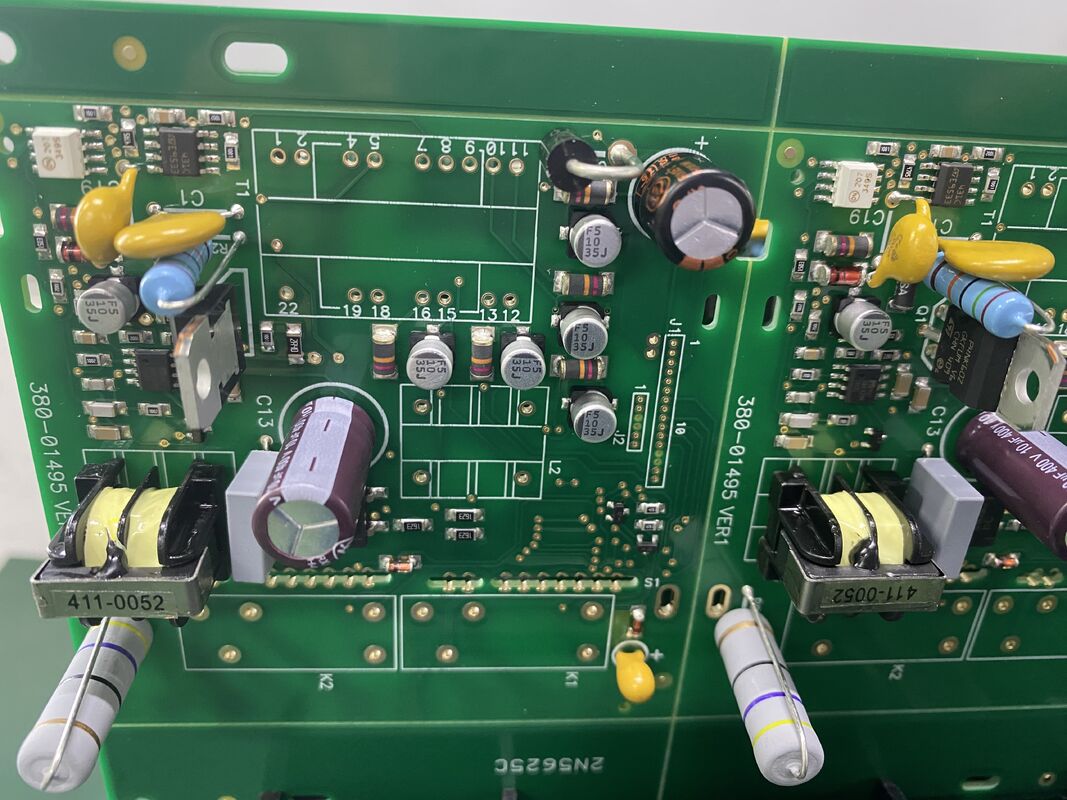

Industrial PCB Assembly plays a critical role in the manufacturing and functionality of modern electronic devices, especially in sectors demanding high reliability and precision. Our Industrial Circuit Board Assembly services are designed to meet the rigorous standards of industrial applications, ensuring robust performance and long-lasting durability. Utilizing top-grade materials such as FR4, CEM-1, and CEM-3, we provide versatile and high-quality Industrial Printed Circuit Assembly solutions suitable for a wide range of industrial environments.

The choice of material is crucial in Industrial PCB Assembly as it directly impacts the board's durability, thermal resistance, and electrical performance. FR4 is widely recognized for its excellent mechanical strength and flame-retardant properties, making it an ideal choice for many industrial applications. CEM-1 and CEM-3 offer cost-effective alternatives with reliable insulation and structural integrity, catering to specific project requirements where flexibility and budget considerations are important. Our ability to work with these materials ensures that we can tailor Industrial PCB Assembly solutions that perfectly fit the unique needs of each client.

Thickness is another vital factor in Industrial Circuit Board Assembly, influencing the board’s mechanical strength and thermal management capabilities. We offer PCB thickness options ranging from as thin as 0.3mm up to 6mm, accommodating a variety of industrial applications. For projects requiring enhanced durability and support, we provide customized boards with a maximum thickness exceeding 4.5mm. This range of thickness options enables us to deliver Industrial Printed Circuit Assembly services that meet diverse operational demands, from lightweight, compact devices to heavy-duty industrial machinery.

Customization is at the core of our Industrial PCB Assembly solutions. Understanding that every industrial application has unique requirements, we offer fully customizable PCB assemblies. Whether you need specific material combinations, precise thickness specifications, or tailored layouts, our team works closely with you to develop Industrial Circuit Board Assembly products that align perfectly with your technical and operational needs. This commitment to customization ensures that our solutions not only meet but exceed industry standards and client expectations.

Quality assurance is paramount in Industrial Printed Circuit Assembly, as these boards often operate in critical and harsh environments. To guarantee the highest quality and reliability, we implement comprehensive testing services, including 100% Automated Optical Inspection (AOI), Functional Circuit Testing (FCT), and In-Circuit Testing (ICT). These rigorous testing protocols ensure that every Industrial PCB Assembly leaving our facility is free from defects, fully functional, and ready to perform under demanding industrial conditions. Our dedication to quality control minimizes failure rates and extends the lifespan of the assembled boards.

Our Industrial PCB Assembly solutions cater to a broad spectrum of industries, including automotive, aerospace, telecommunications, manufacturing automation, and more. By combining premium materials like FR4, CEM-1, and CEM-3 with flexible thickness options and advanced testing services, we provide reliable and efficient Industrial Printed Circuit Assembly products that help drive innovation and productivity. Our extensive experience and technical expertise empower us to deliver tailored Industrial Circuit Board Assembly services that support your project’s success from prototype to mass production.

In summary, our Industrial PCB Assembly services offer a comprehensive solution for industrial electronic applications. With a focus on high-quality materials, customizable thickness ranging from 0.3mm to over 4.5mm, and stringent 100% AOI, FCT, and ICT testing, we ensure that every Industrial Printed Circuit Assembly we produce meets the highest standards of performance and reliability. Partner with us to access cutting-edge Industrial PCB Assembly solutions designed to enhance your products’ functionality and durability in the most challenging industrial environments.

Features:

- Product Name: Industrial PCB Assembly

- Warranty: 1 Year

- Silkscreen Color Options: White, Black, Yellow, Etc.

- Maximum Thickness: T>4.5mm

- Maximum PCB Size: 600*1200mm

- Material Compatibility: FR4, CEM-1, CEM-3

- Advanced Industrial PCB Manufacturing Process ensures high-quality output

- Expert Industrial Circuit Board Assembly for reliable electronic solutions

- Specialized Industrial Electronic Circuit Assembly to meet diverse application needs

Technical Parameters:

| Pcb Thickness |

0.2-3.2mm |

| Max Thickness |

T>4.5mm |

| Soldermask Color |

Green, Red, Blue, Black, White, Yellow |

| Testing Service |

100% AOI FCT ICT Testing |

| Silkscreen Color |

White, Black, Yellow, Etc. |

| Usage |

OEM Electronics |

| Impedance Control |

Yes |

| Customized |

Yes |

| Thickness |

0.3mm-6mm |

| Max Pcb Size |

600*1200mm |

Applications:

Industrial PCB Assembly plays a crucial role in various application occasions and scenarios where precision, reliability, and advanced manufacturing capabilities are essential. With a minimum ball space of 0.3mm≤Pitch<0.5mm, this product supports high-density component placement, making it ideal for complex industrial electronic circuit assembly projects that demand compact and efficient designs.

One common application occasion for Industrial PCB Fabrication Assembly is in the manufacturing of control systems for heavy machinery and automation equipment. These systems require robust and highly reliable printed circuit boards to ensure continuous operation in harsh industrial environments. The capability to handle PCB sizes up to 600*1200mm allows for the production of large and sophisticated circuit boards that meet the demanding specifications of industrial automation.

Another important scenario is in the development of power management units and industrial sensors. The precise impedance control feature ensures signal integrity and minimizes electromagnetic interference, which is critical for maintaining the accuracy and stability of industrial electronic circuit assembly. The flexibility to use materials such as FR4, CEM-1, and CEM-3, along with PCB thickness ranging from 0.2mm to 3.2mm, provides versatility to meet diverse electrical and mechanical requirements across various industrial applications.

Industrial PCB Assembly Solutions are also widely used in telecommunications infrastructure, medical devices, and transportation systems where durability and performance are paramount. The advanced assembly processes accommodate fine-pitch components and complex multilayer designs, enabling the creation of high-performance electronic circuits that support critical industrial functions.

In summary, Industrial PCB Assembly is essential for a wide range of industrial applications, including automation, power management, telecommunications, and transportation. Its ability to support fine pitch components, large PCB sizes, controlled impedance, and various material types ensures that manufacturers can deliver reliable and high-quality industrial electronic circuit assembly tailored to the specific needs of their projects. These Industrial PCB Assembly Solutions provide the foundation for innovative and dependable industrial electronic products.

Customization:

Our Industrial Electronics Assembly Service offers comprehensive product customization for Industrial PCB Fabrication Assembly, ensuring high-quality and reliable solutions tailored to your specific needs. We use premium materials such as FR4, CEM-1, and CEM-3 to manufacture durable and efficient PCBs. To meet diverse design requirements, we provide silkscreen color options including white, black, yellow, and more.

With a maximum board thickness exceeding 4.5mm, our service accommodates robust industrial applications. We guarantee the quality of our assemblies with a 1-year warranty, giving you peace of mind in your investment. Additionally, our 100% AOI, FCT, and ICT testing services ensure every product meets stringent quality standards before delivery.

Choose our Industrial Electronics Assembly Service for expert Industrial PCB Fabrication Assembly that combines quality materials, thorough testing, and customizable options to support your industrial electronics projects effectively.

Support and Services:

Our Industrial PCB Assembly product is supported by a dedicated technical support team committed to ensuring optimal performance and reliability. We provide comprehensive assistance throughout the product lifecycle, including installation guidance, troubleshooting, and maintenance advice. Our experts are equipped to help with process optimization, quality control, and compliance with industry standards. Additionally, we offer customized training sessions and detailed documentation to empower your team with the knowledge needed for efficient operation. Our services also include repair and refurbishment options to extend the lifespan of your assemblies, ensuring minimal downtime and sustained productivity.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each PCB is securely placed in anti-static packaging to prevent electrostatic discharge damage. The assemblies are then cushioned with foam or bubble wrap and packed in sturdy, double-walled corrugated boxes to withstand handling and shipping stresses.

For shipping, we use reliable carriers with tracking options to guarantee timely and safe delivery. Additionally, we offer customized packaging solutions to meet specific client requirements, including moisture barrier bags, desiccants, and temperature-controlled shipping if needed. All packages are clearly labeled with handling instructions and product details to facilitate smooth logistics and inventory management.

FAQ:

Q1: What types of PCBs can you assemble for industrial applications?

A1: We can assemble a wide range of PCB types including single-sided, double-sided, and multi-layer boards suitable for various industrial applications.

Q2: What components do you support for industrial PCB assembly?

A2: We support through-hole, surface-mount, and mixed technology components, including resistors, capacitors, ICs, connectors, and specialized industrial-grade parts.

Q3: What is the typical turnaround time for industrial PCB assembly orders?

A3: Our standard turnaround time ranges from 7 to 15 business days depending on the complexity and volume of the order. Expedited services are available upon request.

Q4: Do you provide testing and quality assurance for assembled PCBs?

A4: Yes, we perform rigorous quality checks including visual inspection, automated optical inspection (AOI), and functional testing to ensure reliability and performance.

Q5: Can you handle high-volume production runs for industrial PCB assemblies?

A5: Absolutely, we are equipped to manage both small prototype batches and large-scale production runs, ensuring consistent quality and timely delivery.

Applications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!