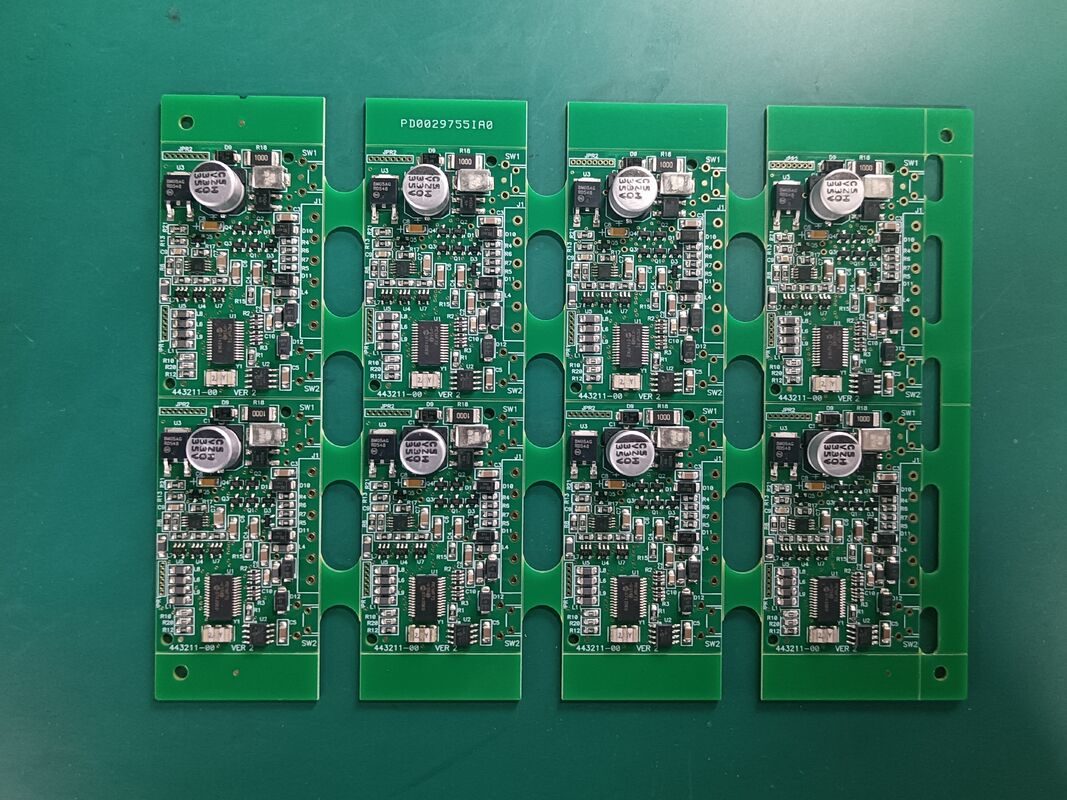

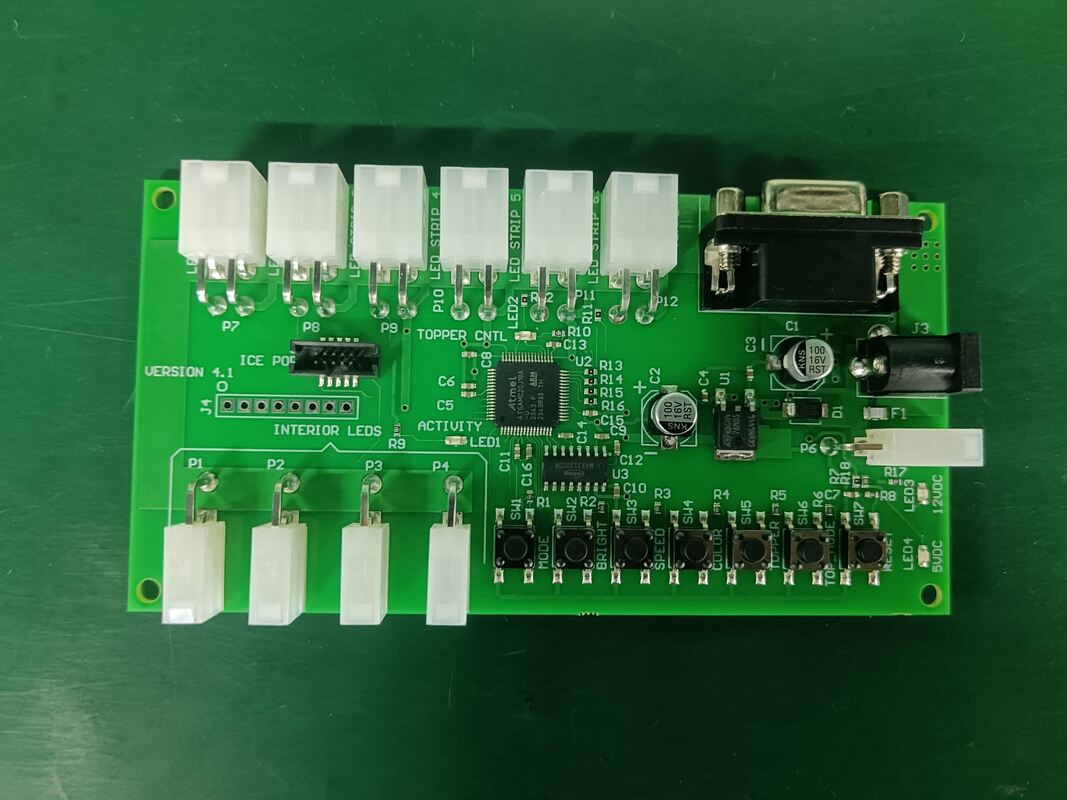

Industrial PCB Assembly IATF 16949 Certified Manufacturer

Suntek Group is a contract supplier in EMS field with one-stop solution for FCB/FPC assembly, Cable assembly, and Box-build assembly.

About Suntek Group

Suntek Electronics Co., Ltd, as the major facility, located in Hunan Prov, China; BLSuntek Electronics Co., Ltd, as the new facility, located in Kandal Prov, Cambodia. With ISO9001:2015, ISO13485:2016, IATF 16949:2016 and UL E476377 certified, We deliver qualified products with competitive price to clients all over the world.

Our Manufacturing Capability

| Item | Parameter |

|---|

| Board Type | Rigid PCB, Flexible PCB, metal core PCB, Rigid-Flex PCB |

| Board Shape | Rectangular, Circular and any irregular Shapes |

| Max Size | 400mm * 1200mm |

| Min Package | 0201 |

| Fine Pitch Parts | 0.25mm |

| BGA Package | Acceptable |

| DIP Capacity | 3 DIP lines and 1 AI assembly line |

| Parts Sourcing | All by Suntek or partial consigned by customer |

| Parts Package | Reels, Cut Tape, Tube & Tray, Loose Parts and Bulk |

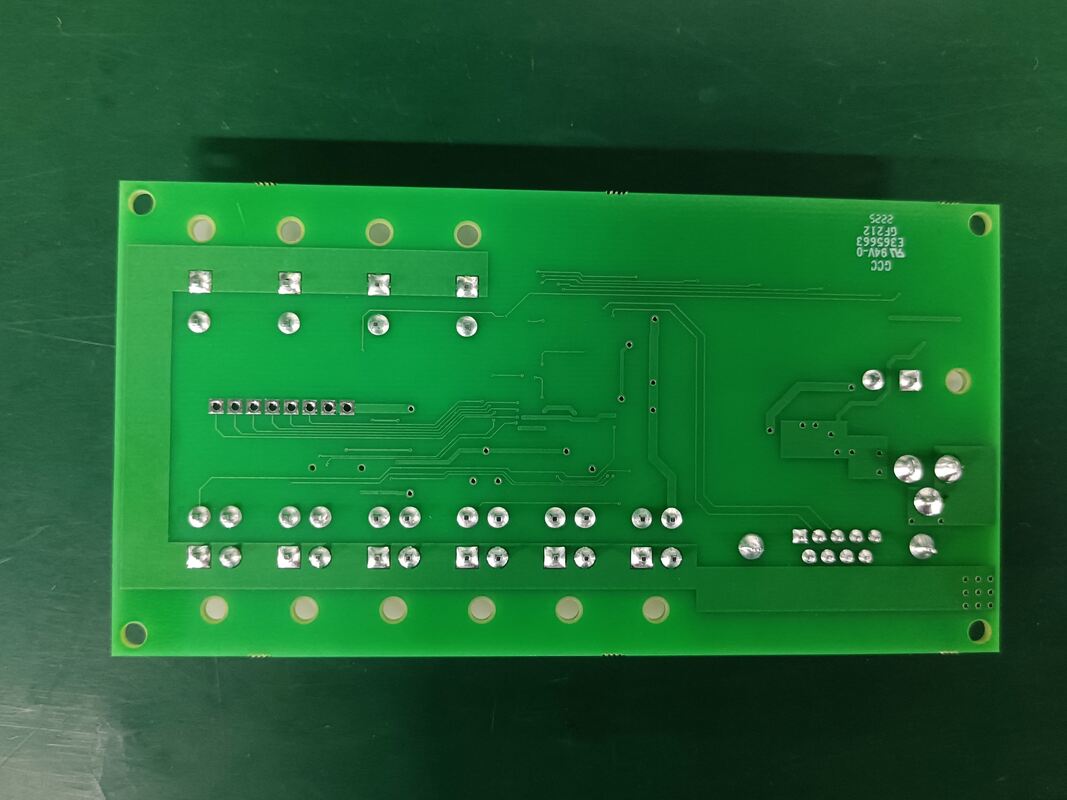

| Testing | Visual inspection, AOI, X-RAY, Functional Testing |

| Types of Solder | Lead or Lead-free (RoHS Compliant) assembly |

| Assembly Option | Surface mount (SMT), Through-hole (DIP), Mixed technology (SMT & Thru-hole) |

| Stencils | Laser cut stainless steel stencils, step-down stencil |

| File Formats | Bill of Materials, PCB (Gerber Files), Pick-N-Place File (XYRS) |

| Quality Grade | IPC-A-610 Class 2/Class 3 |

Application Industries

- Medical Devices: Patient monitors, diagnostic equipment, surgical tools, wearable health tech

- Automotive Electronics: ADAS sensors, engine control units (ECUs), infotainment systems, lighting controls

- Industrial Electronics: Process controls, power supplies, robotics, IoT gateways

- Telecommunications: Network hardware, baseband units, routing equipment

- Consumer Appliances: High-reliability smart home systems and appliances

Our Service Offerings

- PCB and FPC bare board

- PCB and FPC assembly

- Components purchasing and materials customization

- One-stop turnkey box build assembly

- Mixed technology assembly

- Cable assembly and wire harness

- Low/mid/high volume PCB assembly

- BGA/QFN/DFN with X-ray inspection

- IC programming/AOI/ICT/Functional test

PCB Assembly Process

- Our equipment includes Desen Printing press, Samsung SMT, JT lead-free re-flow ovens, lead-free wave-soldering, BGA rework base, AI machine

- Surface mount, through-hole, BGA, QFP and QFN, 0201 parts assembling

- AOI testing (X-ray for BGA package) for every piece board

- First article inspection before SMD process and first completed sample before DIP process

- Programming and function testing

- Conformal coating and Glue

Our Competitive Advantages

Quick Response

Reasonable pricing based on quality standards with comprehensive one-stop service including components and OEM support.

Reliability

All products manufactured according to your design specifications with 1-year warranty on all items.

Confidentiality

Strict protection of intellectual property throughout the entire process with employees working under confidentiality agreements.

Flexibility

Custom PCB prototypes and small PCB assembly orders including SMD, BGA and through-hole. Prototype lead time: 3-5 working days. Standard production: 7-10 working days.

Customer Support & Services

- 24-hour response to complaints, issues and queries

- Weekly progress reports

- Dedicated customer support team

- Customer satisfaction questionnaires

- 1-year guarantee period for all products

- Free of charge repair services

- Quick replacement of defective parts

- Transparent cost breakdown and BOM sharing

- Global component supplier network

- Structured communication procedures for schedule delays or quality issues

Frequently Asked Questions

Q1: What files do you use in PCB fabrication?

A1: Gerber, PCB, Auto CAD

Q2: How do you make sure the quality?

A2: Our products are 100% E-tested. PCB assemblies undergo 100% AOI, ICT, FT and visual checking, with 100% X-ray for BGA components.

Q3: Can we visit your company?

A3: Welcome to visit our company located in Xingsha Industrial Park, Changsha, Hunan province, China.

Q4: What is the lead time?

A4: Samples: 3-5 working days. Batch production: 7-10 working days. PCB assembly: 15-20 working days.

Q5: Will you keep our information and files secret?

A5: Protection of business secrets is our fundamental principle. NDA can be signed at any time.

Q6: How to work with you?

A6: Email us your PCB layout file and BOM list. We provide confirmation within 12 hours and pricing within 3-5 days.

We have advanced manufacturing equipment and technology, professional engineering teams, purchasing teams, quality teams and management teams to guarantee high quality products and on-time delivery. Our products are widely used in industrial control, automotive, telecommunications, medical equipment, consumer electronics and more.

With ISO9001:2015, ISO13485:2016, IATF 16949:2016 and UL E476377 certified.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!