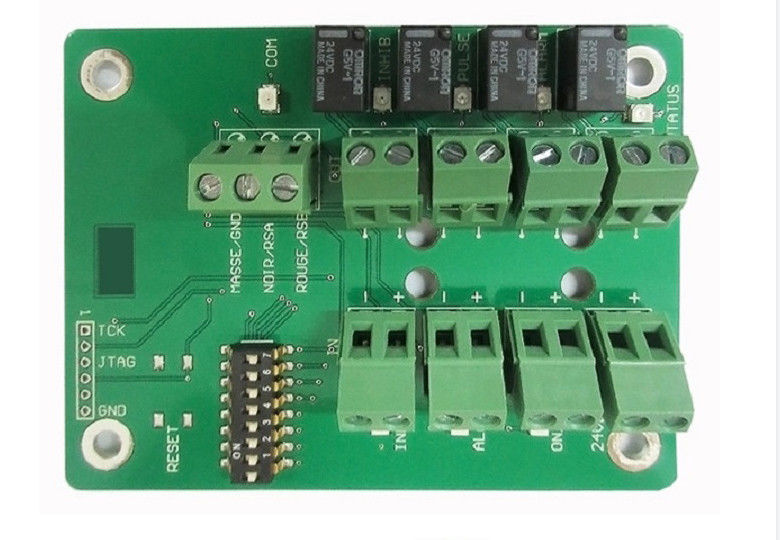

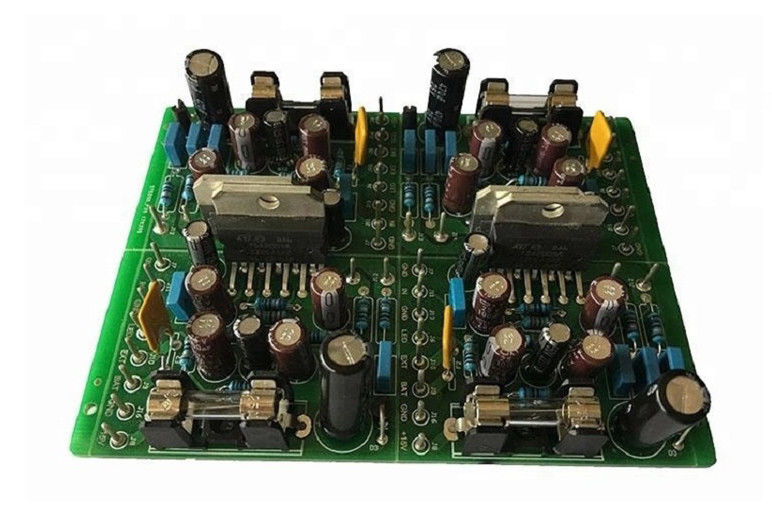

Suntek Group is a leading supplier in EMS field with one-stop solution for PCB/FPC

assembly,Cable assembly,Mix technology assembly and Box-buildings.

Suntek Electronics Co., Ltd,as the major facility, located in Hunan Prov,China;

BLSuntek Electronics Co., Ltd,as the new facility,located in Kandal Prov,Cambodia.

Technical Parameters:

Applications:

Automotive PCB Assembly: The Perfect Solution for Motor Vehicle Electronics

The Automotive PCB Assembly is a cutting-edge product that provides high-quality and reliable electronic solutions for motor vehicles. With its advanced technology and top-notch features, this product is the ideal choice for Truck Electronic Module Assembly, Vehicular Printed Circuit Board Assembly, Automotive Electronic Components, Automotive PCB Manufacturing, and Automobile Electronics Assembly.

Product Features:

Plugging Vias Capability: 0.2-0.8mm

Surface Finished: ENIG (Electroless Nickel Immersion Gold)

Layers: 1-60

Pcba Test: AOI (Automated Optical Inspection), X-RAY, ICT (In-Circuit Test), and Function Test

Minimum Hole Tolerance: ±0.05mm

The testing standards we follow for automotive PCBs

Automotive printed circuit boards should be manufactured and tested as per certain guidelines and standards. Some of the important standards are:

- IPC-6012DA: Ensures the reliability of circuit boards used in electronic interconnects that are exposed to high vibration and heat.

- AEC-Q100: Includes failure test qualifications for ICs.

- AEC-Q101: Identifies failure test qualifications for discrete semiconductors.

- AEC-Q102: Includes failure test qualifications for discrete optoelectronic semiconductors.

- AEC-Q104: Defines failure test qualifications for discrete optoelectronic semiconductors.

- AEC-Q200: Defines failure test qualifications for passive components.

- IPC-6011: Illustrates the performance standards and specifications for PCBs.

Benefits of using Automotive PCB Assembly:

- High-quality and reliable electronic solutions

- Efficient and accurate performance

- Advanced technology for optimum results

- Cost-effective and time-saving solution

- Customized options available for specific needs

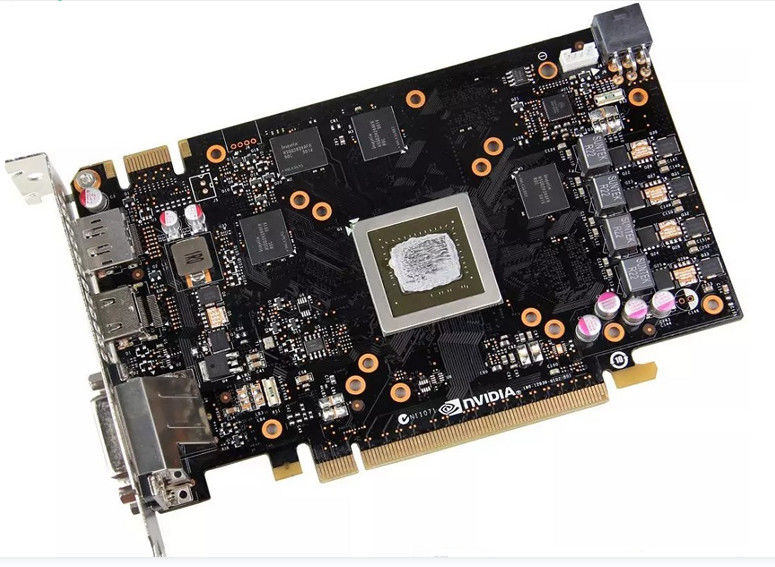

What Is the Difference Between PCBA and PCB?

Printed circuit board (PCB) and printed circuit board assembly (PCBA) are both important terms in the electronics industry. Some people use them interchangeably, but they are actually two distinct things.

The main difference between these two terms is that PCB refers to a blank circuitry board, while PCBA refers to a board that contains all of the necessary electronic components for the board to function as needed. A PCB is not yet functional because it does not have the required components in place, while a PCBA is a complete and functional board. PCBs and PCBAs are two different parts of the same process — a PCBA is built on top of an existing PCB.

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

How to get a quote for automotive PCBs

Let us run DFM/DFA analysis for you and get back to you with a report. You can upload your files securely through our website.

We require the following information in order to give you a quote:

- Gerber, ODB++ or IPC-2581

- BOM if you require assembly

- Quantity

- Turn time

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!