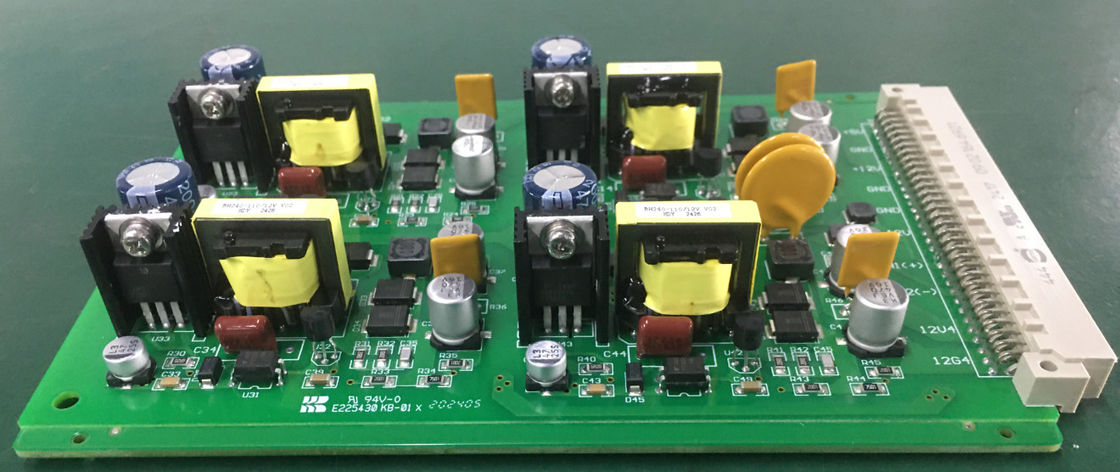

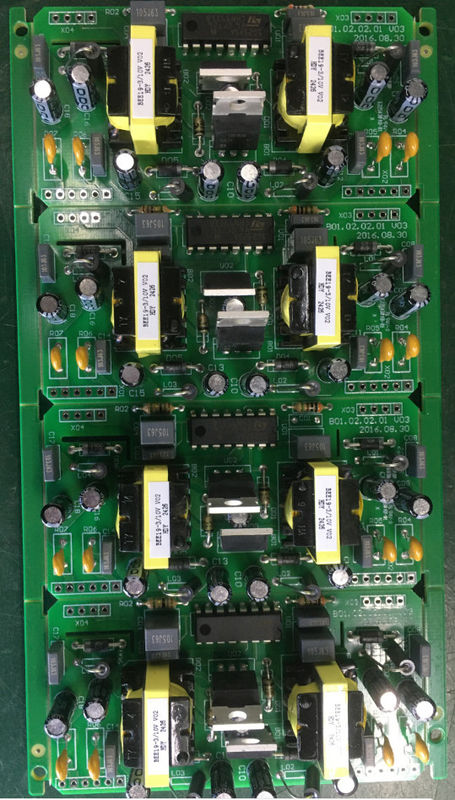

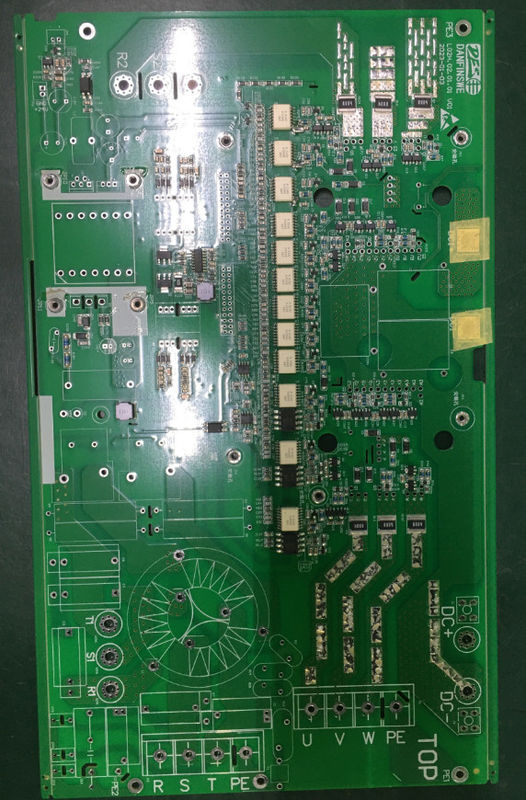

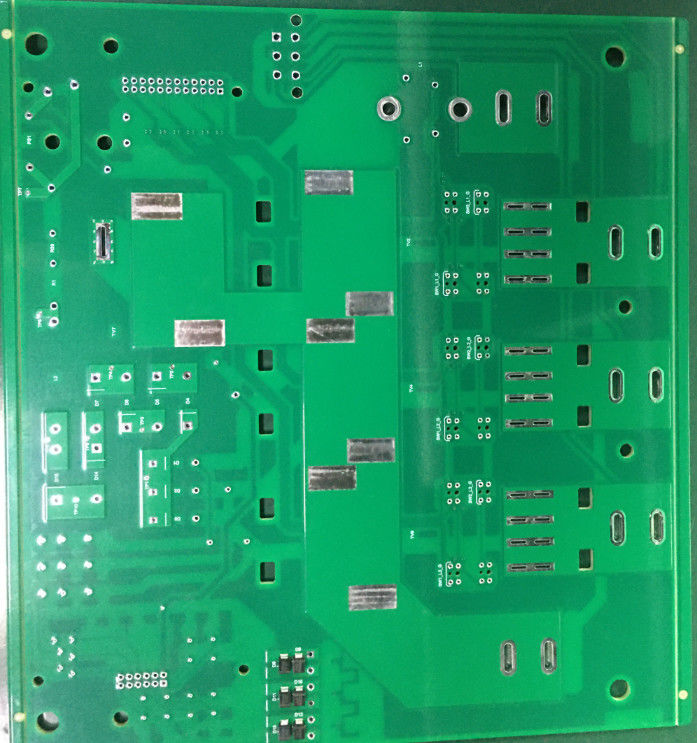

Suntek Group is a leading supplier in EMS field with one-stop solution for PCB/FPC

assembly,Cable assembly,Mix technology assembly and Box-buildings.

Suntek Electronics Co., Ltd,as the major facility, located in Hunan Prov,China;

BLSuntek Electronics Co., Ltd,as the new facility,located in Kandal Prov,Cambodia.

Defining Industrial PCBs

Industrial PCBs differentiate on:

Operating Environments – Made for extreme industrial settings with wider temperature (-40°C to 105+°C), shock/vibration, humidity and other environmental demands.

Lifespan – Designed for high reliability over long product field life, often 10-15+ years of near continuous operations.

Criticality – High availability, functionality and safety criticality if the PCB fails. Whole industrial systems may rely on them.

Some examples of electronics using specially designed industrial class PCBs include:

Ruggedness, extended lifespan and high reliability distinguish industrial PCBs even though they may resemble commercial boards upon visual inspection. Their unique constraints lead to various design and manufacturing rules.

What does PCBA Stand for in Electronics?

PCBA stands for Printed Circuit Board Assembly. It refers to the process of soldering electronic components to a printed circuit board (PCB) to create a functional circuit. The PCB is essentially the backbone of electronic devices, providing a solid foundation for components and facilitating connections between them. The assembly process involves soldering components to the board, and this completed assembly is then referred to as PCBA.

Substrates

| Layers: |

Rigid PCB 2 - 40 + Layers, Rigid-flex PCB 1 - 10Layers |

| Panel Size(max): |

21" x 24" |

| PCB Thickness: |

0.016" to 0.120" |

| Line & Spaces: |

0.003" / 0.003" Inner Layers; 0.004" Outer Layers |

| Hole Size: |

0.006" Thru Hole (Finished Size) and 0.004" Buried Via |

| Materials: |

FR4, High Tg, Rogers, Halogen-free material, Teflon, Polyimide |

| Surface Finishes: |

ENi/IAu, OSP, Lead-free HASL,Immersion Gold/Silver, Immersion Tin |

| Special Products: |

Blind/ Buried Via(HDI 2+N+2), Rigid Flex |

How are industrial PCBs different than commercial PCBs?

· Longer field deployment lifetimes (10-20 years)

· Required survival through harsh vibration, shock, moisture conditions

· High availability and uptime (>99%)

· Rigorous product testing and qualification

· Precision manufacturing process controls

· Traceability documentation Which exceeds commercial PCB environmental and lifespan demands.

What are some ways engineers design industrial PCB layouts differently?

Design techniques used for industrial printed circuit boards include:

- Component derating below absolute maximum levels

- Thermal simulation using finite element models

- Redundant connections and pathways

- Vibration damping edge mount connectors

- Conformal coating for moisture protection

- Thicker power and ground traces

- Double sided boards to withstand shock

- Extensive DFM analysis before release

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

Our core is "Quality wins Market, ldeas create the Future".

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!