Suntek Group is a professional supplier in EMS field with one-stop solution for PCB ,PCB assembly ,cable assembly,Mix. Technology assembly and box-building. With ISO9001:2015,ISO13485:2016,IATF 16949:2016 and UL E476377 certified.We deliver qualified products with competitive price to clients all over the world.

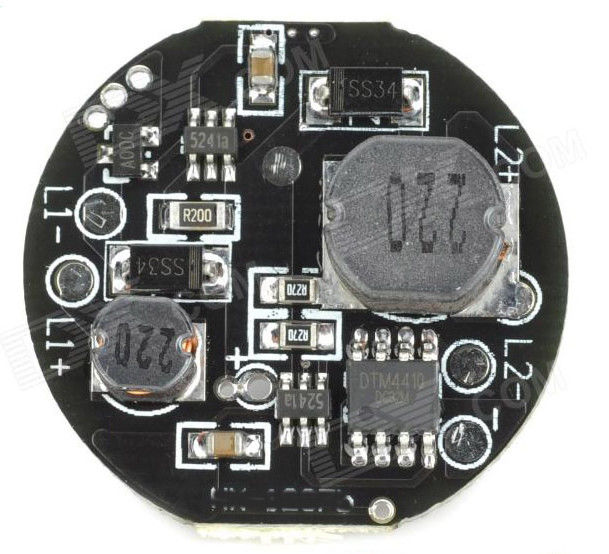

| Specifications |

Details |

| Material type |

FR-1, FR-4, CEM-1, aluminum clad |

| Material thickness ( mm) |

0.4, 0.6, 0.8, 1.0, 1.2, 1.6, 2.0 |

| Layer count |

1 to 8 Layers |

| Max. Board size |

23.00” x 35.00”(580mm*900mm) |

| IPC class |

Class II, Class III , Class 1 |

| Annular ring |

5 mil/side or Greater (Min. Design) |

| Finish plating |

Solder(HASL), Lead Free Solder(HASL), ENIG (Electroless nickel

immersion gold), OSP, immersion silver, immersion tin, immersion nickel,

hard gold, other

|

| Copper weight |

0.5OZ-2OZ |

| Trace/space width |

3 Mils or greater |

| Drill clearance |

0.1mm(laser drilling) |

| Plated slots |

0.036 or greater |

| Smallest hole (finished) |

0.1mm or greater |

| Gold fingers |

1 to 4 Edge (30 to 50 Micron Gold) |

| SMD pitch |

0.080” - 0.020” - 0.010” |

| Solder mask type |

LPI Glossy, LPI-Matte, SR1000 |

| Solder mask color |

Green, red, blue, black, white, yellow |

| Legend color |

White, yellow, black, red, blue |

| CNC route point |

Any |

| Minimum route width |

0.031” |

| Scoring |

Straight lines, jump scoring, panel edge to edge, CNC* |

| Body gold |

HARD*, IMMERSION* (up to 50 MICRON GOLD) |

| Data file format |

Gerber 274x with embedder aperture |

| FAB. Drawing format |

DXF, HPGL, DWG, PDF, Gerber |

| E.T testing |

Flying probe, single sided, 1up plate, clamp shell, net list |

| Counter sink/counter bore |

Available up to 0.250 Diameter |

| Control impedance |

Yes |

| Blind vias/buried vias |

Yes |

| Peelable mask |

Yes |

| Carbon |

Yes |

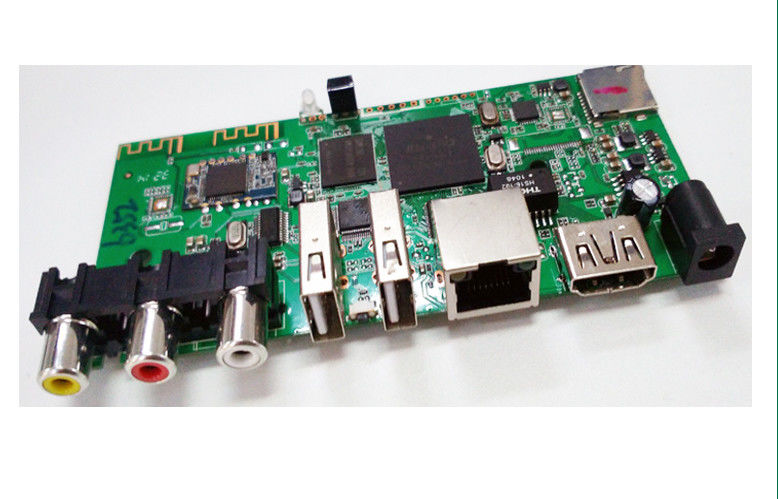

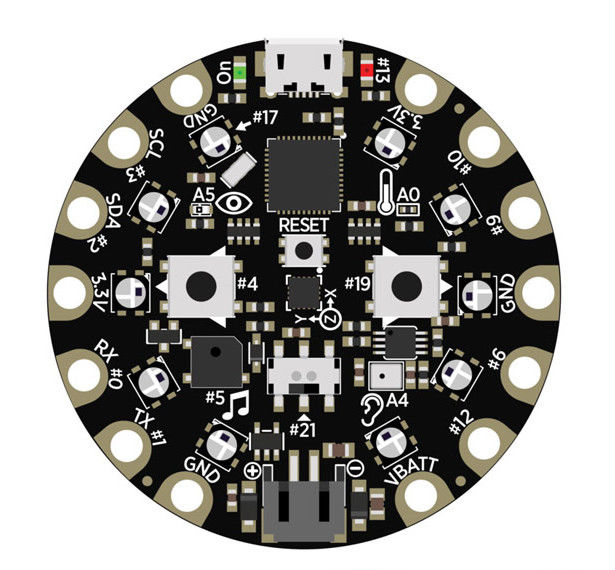

What is the advantages of SMT assembly?

1. High density SMT assembly: Based on technology development, electronic products becomes smarter and smarter, more and more sophisticated, it required that PCB assembly density need to be greatly improved. And SMT assembly solved this problem perfectly, it makes high density PCB assembly become possible.

2. Lower cost and faster produce speed: due to the features of standardization, automation and holeless mounting, smaller-size components mounting reduce a lot of cost than their larger through-hole PCB, reduce drilling and increase the speed of produce.

3. Higher performance: Using electronic components with short-lead or no-lead, SMT assembly reduce parasitic inductance and capacitance from the leads, improves the frequency and speed performance of PCB. Keep the PCB and components out of heat effectively.

4. Reliable and stable: automated production machines ensures that every connection of the components are soldered well, SMT assembly improve the reliability and stability of electronic products.

5.More efficient use of pcb area: smaller electronic components and the technology of SMT allow SMT assembly to have a better use on the PCB's surface area.

6.SMT assembly helps PCBs circuits faster

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

Packaging:

The Flexible PCB Assembly product will be packaged in a sturdy cardboard box to ensure safe transportation. The box will be sealed with tape to prevent any damage during shipping.

The product will also be wrapped in bubble wrap to provide extra protection against potential impact and vibration during transit.

Each box will be labeled with the product name, quantity, and handling instructions to facilitate easy identification and handling.

Shipping:

The product will be shipped via a reliable and trusted courier service to ensure timely and secure delivery to the customer.

The shipping address and contact information will be double-checked to ensure accurate delivery. The product will be insured during transit to protect against any unforeseen events.

A tracking number will be provided to the customer once the product has been shipped, allowing them to track their order and ensure its safe arrival.

Upon delivery, the customer will be required to sign for the package as proof of receipt.

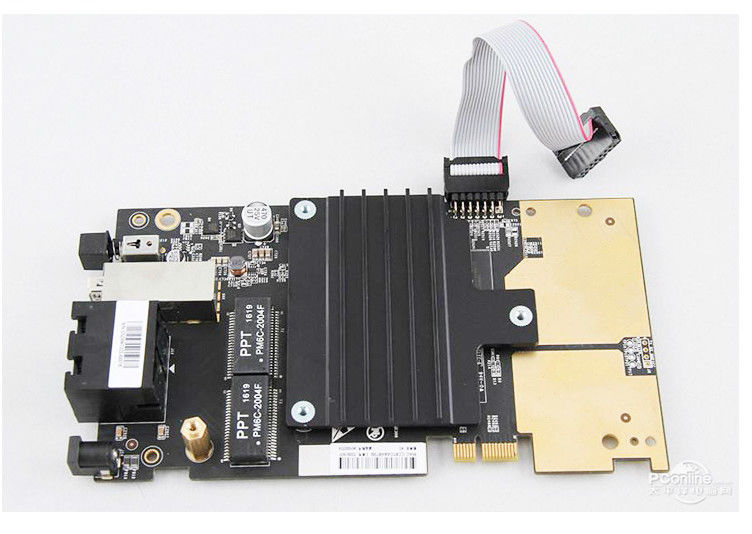

Rigid-Flex product types include:

- Type 1: Single sided flexible material with or without shield(s) or stiffener (one conductive layer).

- Type 2: Double sided flexible material with or without shield(s) or stiffener (two conductor layers) with plated through holes.

- Type 3: Multilayer flexible material with or without shield(s) or stiffener (more than two conductor layers) with plated through holes and HDI.

- Type 4: Multilayer rigid and flexible material combinations (more than two conductor layers) with plated through

- holes and HDI.

Our core is "Quality wins Market, ldeas create the Future".

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!