We provide SMT,THT and final assembly with ICT and functional product test.

Suntek provides a one stop solution for all of your electronic manufacturing services requirements, ranging from fast turnaround prototyping to high volume manufacturing. We have the capability to identify design and/or production issues during the prototype stage and solve these (in consultation with you) before moving to production.

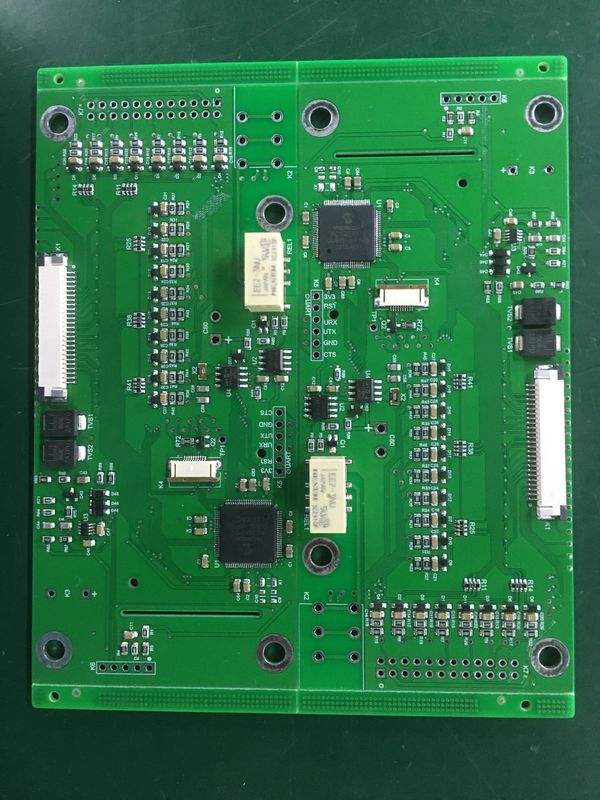

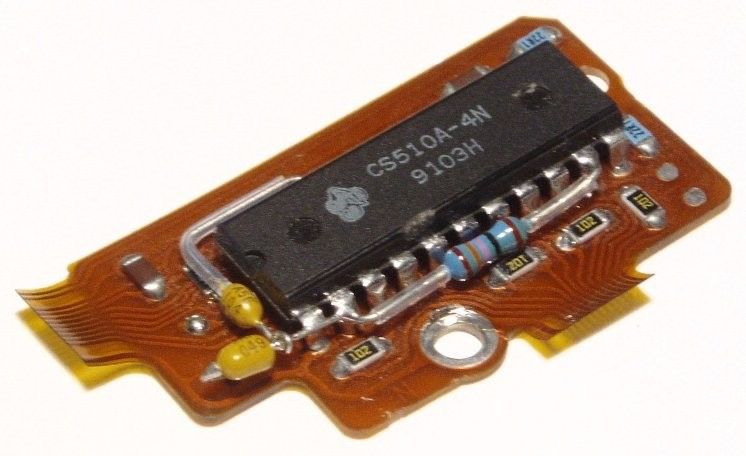

While many PCB houses claim to offer superior PCB assembly services, Suntek actually delivers on what we promise. Our turnkey or consigned printed circuit board assembly service is ISO ISO9001:2015-certified and RoHS compliant. We handle SMD, through-hole and mixed assembly projects, and also offer free DFM checks along with function testing based on your specific requirements.Our PCBA capabilities are listed below:

Capabilities overview:

| Specifications |

Details |

| Material type |

FR-1, FR-4, CEM-1, aluminum clad |

| Material thickness ( mm) |

0.4, 0.6, 0.8, 1.0, 1.2, 1.6, 2.0 |

| Layer count |

1 to 8 Layers |

| Max. Board size |

23.00” x 35.00”(580mm*900mm) |

| IPC class |

Class II, Class III , Class 1 |

| Annular ring |

5 mil/side or Greater (Min. Design) |

| Finish plating |

Solder(HASL), Lead Free Solder(HASL), ENIG (Electroless nickel

immersion gold), OSP, immersion silver, immersion tin, immersion nickel,

hard gold, other

|

| Copper weight |

0.5OZ-2OZ |

| Trace/space width |

3 Mils or greater |

| Drill clearance |

0.1mm(laser drilling) |

| Plated slots |

0.036 or greater |

| Smallest hole (finished) |

0.1mm or greater |

| Gold fingers |

1 to 4 Edge (30 to 50 Micron Gold) |

| SMD pitch |

0.080” - 0.020” - 0.010” |

| Solder mask type |

LPI Glossy, LPI-Matte, SR1000 |

| Solder mask color |

Green, red, blue, black, white, yellow |

| Legend color |

White, yellow, black, red, blue |

| CNC route point |

Any |

| Minimum route width |

0.031” |

| Scoring |

Straight lines, jump scoring, panel edge to edge, CNC* |

| Body gold |

HARD*, IMMERSION* (up to 50 MICRON GOLD) |

| Data file format |

Gerber 274x with embedder aperture |

| FAB. Drawing format |

DXF, HPGL, DWG, PDF, Gerber |

| E.T testing |

Flying probe, single sided, 1up plate, clamp shell, net list |

| Counter sink/counter bore |

Available up to 0.250 Diameter |

| Control impedance |

Yes |

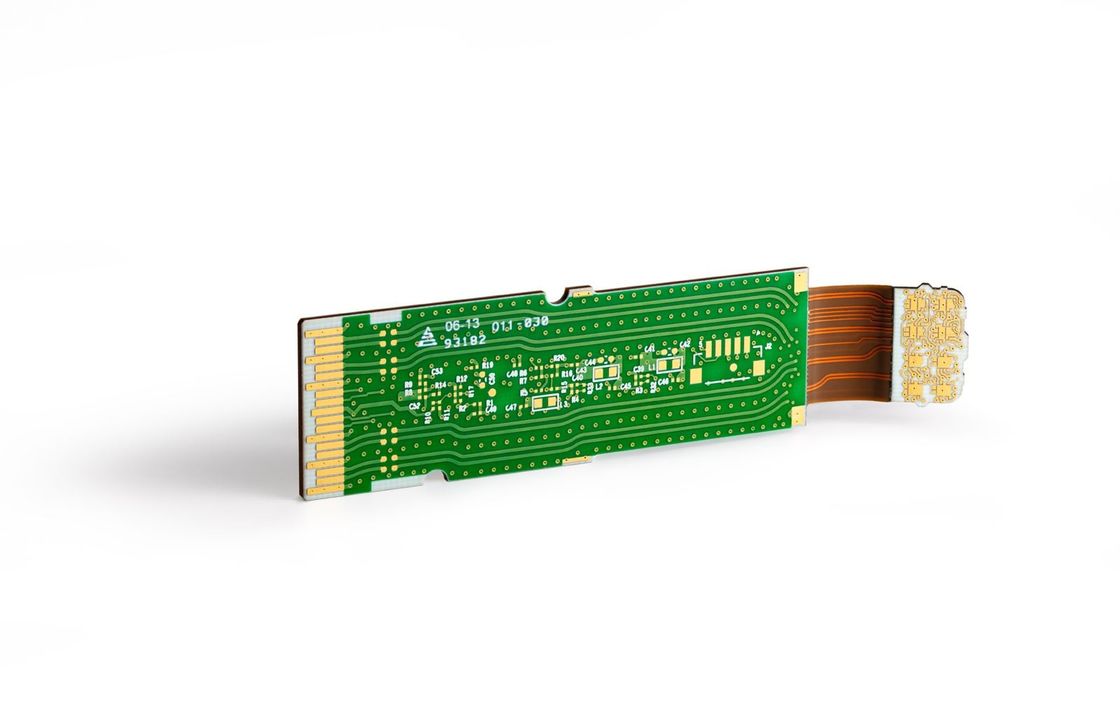

| Blind vias/buried vias |

Yes |

| Peelable mask |

Yes |

| Carbon |

Yes |

Features:

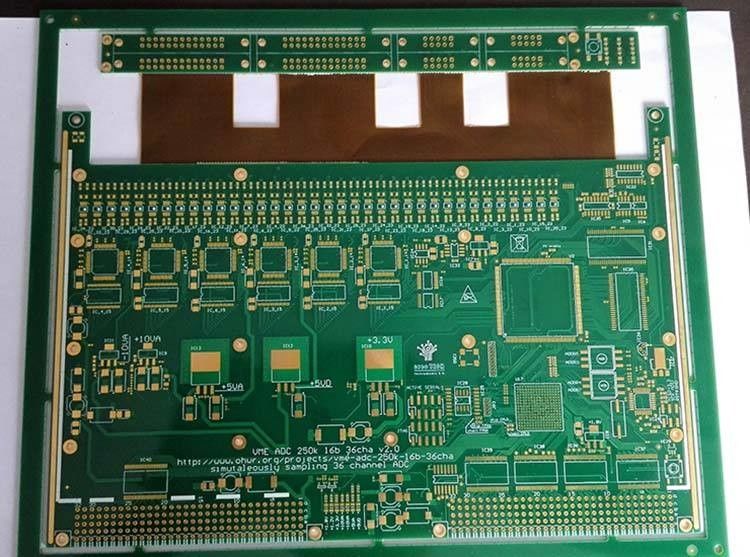

High Density Interconnection Printed Circuit Board

Advanced Interconnect PCB

Multi-Layer PCB

Number Of Layers: 6-Layer

Controlled Impedance: Yes

Small Size: 300 * 210 Mm

High Precision

Diverse Color Options: White, Black, Yellow, Red, Blue, etc.

High Reliability

Applications:

Nanocircuit HDI PCB Board: Revolutionizing Consumer Electronics

Miniaturization | High Performance | Immersion Gold Process

The Nanocircuit HDI PCB Board is an advanced interconnect technology that is changing the game in the world of consumer electronics. With its high-density interconnect design, this PCB board is able to accommodate the increasing demand for smaller and more powerful devices.

The HDI Interconnect Board utilizes the latest immersion gold process, ensuring superior quality and reliability. It undergoes 100% testing to ensure that each and every board meets the highest standards of performance. With its impedance control feature, this PCB board is able to maintain signal integrity and minimize interference, making it ideal for high-speed digital circuits.

One of the key advantages of the Nanocircuit HDI PCB Board is its miniaturization capabilities. As technology continues to advance, the demand for smaller and more compact devices has increased. With its high-density interconnect design, this PCB board is able to accommodate more components in a smaller space, making it the perfect choice for compact consumer electronics such as smartphones, tablets, and wearables.

Not only does the Nanocircuit HDI PCB Board offer miniaturization, it also delivers high performance. Its advanced interconnect technology allows for faster and more efficient data transfer, making it ideal for high-speed digital circuits. This makes it the perfect choice for consumer electronics that require high processing power, such as gaming consoles, laptops, and smart home devices.

The application of the Nanocircuit HDI PCB Board is not limited to consumer electronics. It has also been widely used in industries such as aerospace, medical, and automotive, where high performance and reliability are crucial. With its versatility and superior quality, this PCB board has become a top choice for various applications.

Available in a variety of silkscreen colors such as white, black, yellow, red, blue, and more, the Nanocircuit HDI PCB Board can also be customized to meet specific design requirements. Its sleek and compact design makes it not only functional, but also visually appealing.

In conclusion, the Nanocircuit HDI PCB Board is a game-changer in the world of consumer electronics. Its miniaturization capabilities, high performance, and reliability make it the perfect choice for a wide range of applications. With its advanced interconnect technology and immersion gold process, this PCB board offers the best in quality and performance, setting a new standard for high-density interconnect PCBs.

Packing and Shipping:

HDI PCB Board Packaging and Shipping:

Our HDI PCB boards are carefully packaged and shipped to ensure their safe arrival at your doorstep. Here's a breakdown of our packaging and shipping process:

Packaging:

- All HDI PCB boards are first inspected for any defects or damages before being packaged.

- The boards are then placed in anti-static bags to prevent any static electricity from damaging the components.

- Next, the boards are placed in a sturdy cardboard box with proper cushioning materials to protect them during transit.

- If the order includes multiple boards, they will be individually separated and packaged to prevent any scratching or damage.

- The box is then sealed and labeled with the necessary shipping information.

Shipping:

- We offer various shipping methods to suit your needs, including air, sea, and express delivery.

- All packages are insured to protect against any damages or losses during transit.

- We work with trusted and reliable shipping carriers to ensure timely and secure delivery of your order.Once your order is shipped, we will provide you with a tracking number so you can monitor the status of your delivery.

With our careful packaging and reliable shipping methods, you can rest assured that your HDI PCB boards will arrive at your doorstep in perfect condition. If you have any questions about our packaging and shipping process, please don't hesitate to contact us. We are always happy to assist you with any concerns.

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

Our Target

We are always trying to supply competitive price,high quality,quick-delivery products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!