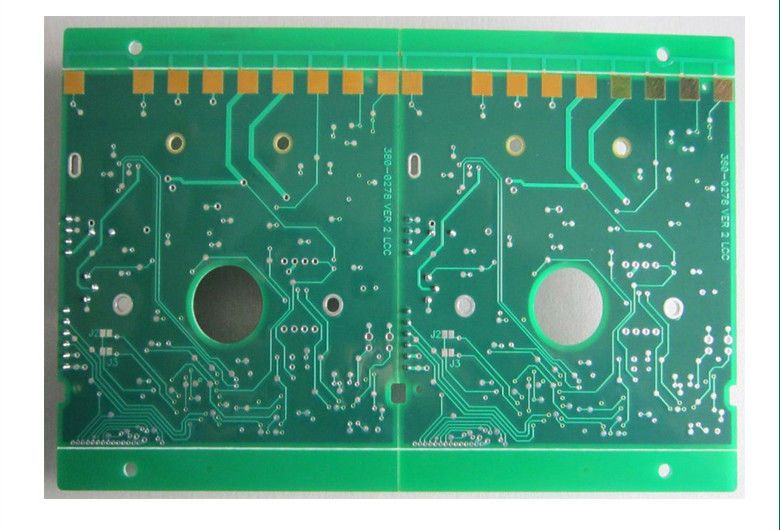

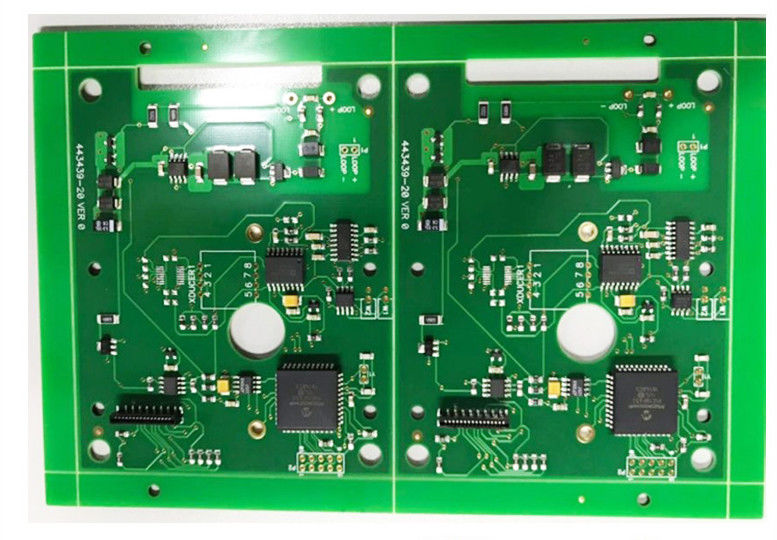

Suntek Group is a leading supplier in EMS field with one-stop solution for PCB/FPC

assembly,Cable assembly,Mix technology assembly and Box-buildings.

Suntek Electronics Co., Ltd,as the major facility, located in Hunan Prov,China;

BLSuntek Electronics Co., Ltd,as the new facility,located in Kandal Prov,Cambodia.

Certificates:

With ISO9001:2015,ISO13485:2016,IATF 16949:2016 and UL E476377 certified,

Choose our Automotive PCB Assembly for a reliable and high-quality circuit integration service for your automotive applications. Contact us today to learn more and get a quote for your project.

Technical Parameters:

|

Product Name

|

Automotive PCB Assembly

|

|

Surface Finished

|

ENIG (Electroless Nickel Immersion Gold)

|

|

Pcb Layers

|

2 Layers

|

|

Pcb Assembly Method

|

BGA (Ball Grid Array)

|

|

Pcb Process

|

Immersion Gold

|

|

Pcba Test

|

SPI, AOI, X-RAY, ICT and Function Test

|

|

Pcb Thickness

|

0.2-7.0mm

|

|

Service

|

PCB&PCBA (Printed Circuit Board & Printed Circuit Board Assembly)

|

|

Material Precision

|

0402+QFN+QFP (0402 Size Components, Quad Flat No-Lead Package, Quad Flat Package)

|

|

Pcb Quality System

|

ROHS (Restriction of Hazardous Substances)

|

|

Pcba Service

|

SMT (Surface Mount Technology) + Function Test

|

|

Key Features

|

Auto PCB Assembly Production, Car PCB Integration and Assembly, Automotive Electronics System Integration

|

Product Features:

Plugging Vias Capability: 0.2-0.8mm

Surface Finished: ENIG (Electroless Nickel Immersion Gold)

Layers: 1-60

Pcba Test: AOI (Automated Optical Inspection), X-RAY, ICT (In-Circuit Test), and Function Test

Minimum Hole Tolerance: ±0.05mm

Application Scenarios:

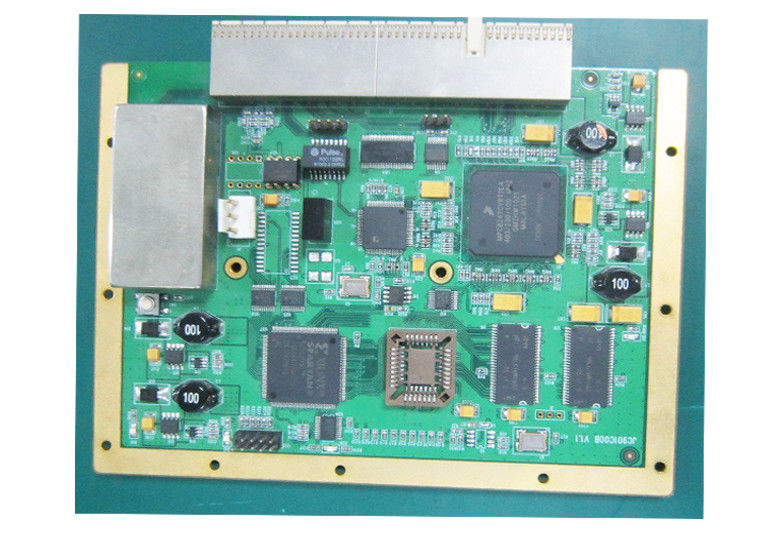

The Automotive PCB Assembly is widely used in the automotive industry for various applications. Some of the common scenarios where this product is utilized include:

Engine Control Units (ECUs):

These are electronic control units that manage and control the engine's functions. The Automotive PCB Assembly is used in the manufacturing of these units to ensure their efficient functioning.

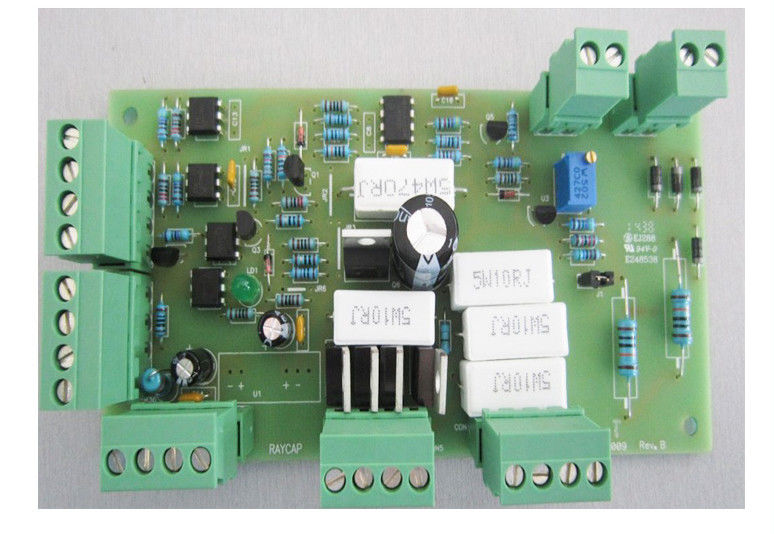

Dashboard Electronics:

The modern-day vehicles are equipped with advanced dashboard electronics that display important information such as speed, fuel level, and engine temperature. The Automotive PCB Assembly is used in the production of these electronics, ensuring their accuracy and reliability.

Safety Systems:

The safety systems in a vehicle, such as airbags, ABS (Anti-lock Braking System), and ESC (Electronic Stability Control), rely on electronic components. The Automotive PCB Assembly is an essential component in the manufacturing of these systems, ensuring their proper functioning.

Entertainment Systems:

The Automotive PCB Assembly is also used in the production of entertainment systems in vehicles, such as audio systems, navigation systems, and rear-seat entertainment systems.

Benefits of using Automotive PCB Assembly:

High-quality and reliable electronic solutions

Efficient and accurate performance

Advanced technology for optimum results

Cost-effective and time-saving solution

Customized options available for specific needs

Automotive Circuit Assembly Service

Our Automotive Circuit Assembly Service offers a wide range of customization options to meet the specific requirements of your automotive electronics. With our expertise in PCB manufacturing and assembly, we can provide high-quality, reliable and cost-effective solutions for your automotive electronic systems.

Automotive Electronics System Integration

We offer comprehensive system integration services to seamlessly integrate your automotive electronics into your vehicle. Our team of experts will work closely with you to ensure that your automotive circuit assembly meets all performance and safety standards.

Get a Quote Today

Contact us today to learn more about our Automotive PCB Assembly Customization Service and how we can help bring your automotive electronics to life. Our team of professionals is ready to assist you with all of your customization needs.

Packing and Shipping:

Automotive PCB Assembly Packaging and Shipping

Packaging:

The Automotive PCB Assembly product will be packaged in a sturdy cardboard box to ensure safe transportation. The box will be sealed with tape to prevent any damage during shipping.

The product will also be wrapped in bubble wrap to provide extra protection against potential impact and vibration during transit.

Each box will be labeled with the product name, quantity, and handling instructions to facilitate easy identification and handling.

Shipping:

The product will be shipped via a reliable and trusted courier service to ensure timely and secure delivery to the customer.

The shipping address and contact information will be double-checked to ensure accurate delivery. The product will be insured during transit to protect against any unforeseen events.

A tracking number will be provided to the customer once the product has been shipped, allowing them to track their order and ensure its safe arrival.

Upon delivery, the customer will be required to sign for the package as proof of receipt.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!